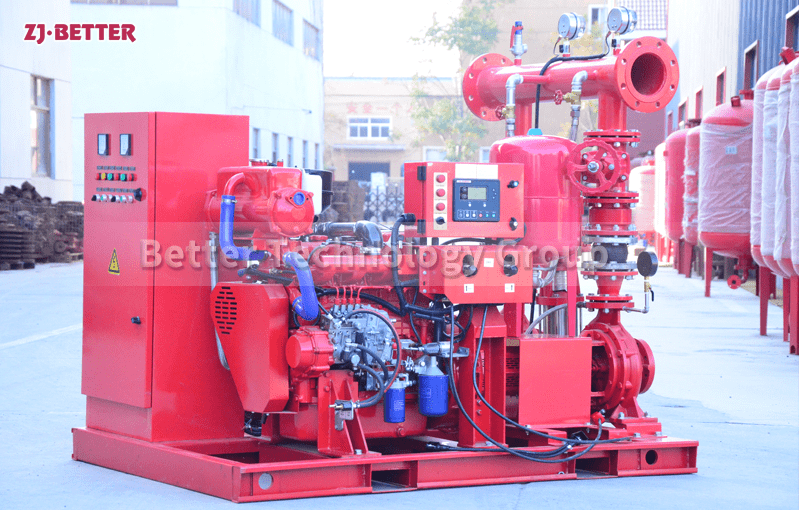

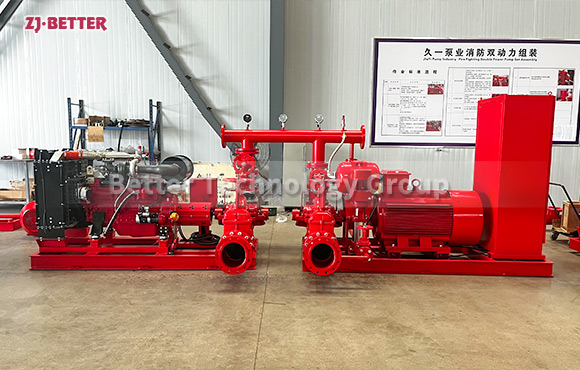

DJ (diesel + jockey) Fire Pump Set

Using Instruction:

Altitude ¡Ü 1000m;

Ambient temperature: +5 ¡ãC ~ +40 ¡ãC;

Relative humidity: <= 90%.

Application Scope:

Equipment for warehouses, docks, airports, petrochemical, power plants, liquefied gas, textiles, ships, oil tankers and other occasions of a fire service.

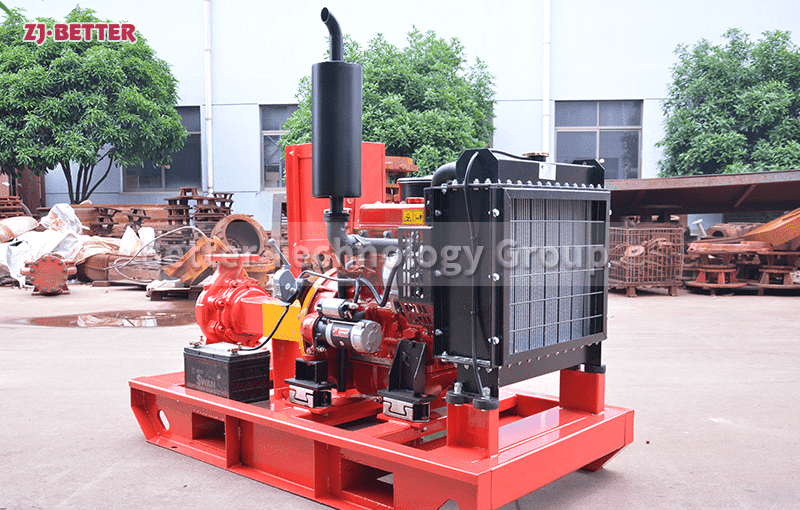

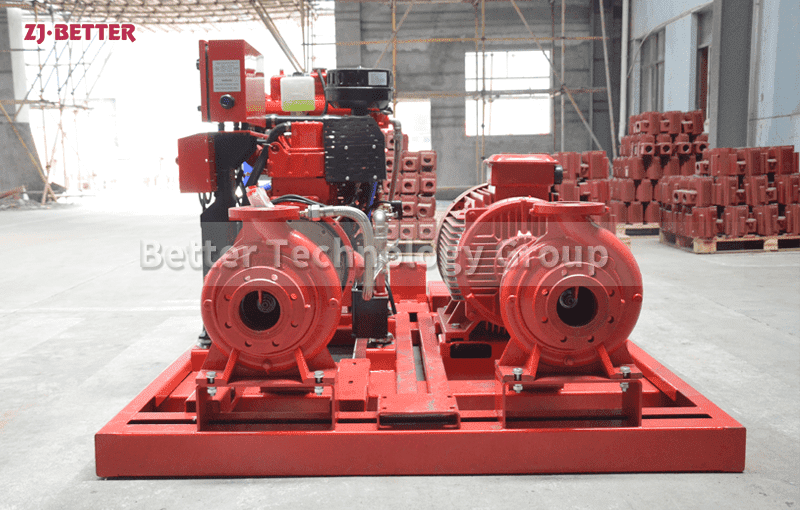

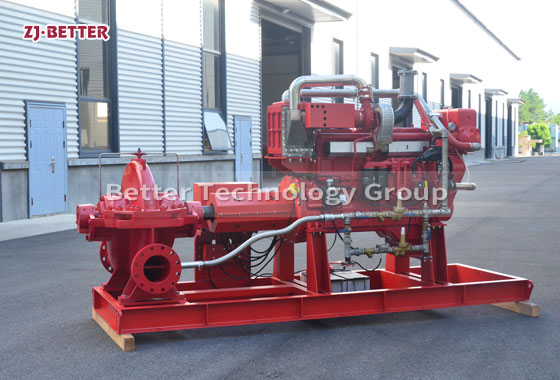

1. Diesel engine pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller , with fuel tank, water tank£¬fan, control box

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing :cast iron ,shaft and impeller SS304

3. Control panel: Auto Control of diesel engine pump and Jockey Pump with overload, over current protection

4. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, Pressure Gauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Base plant