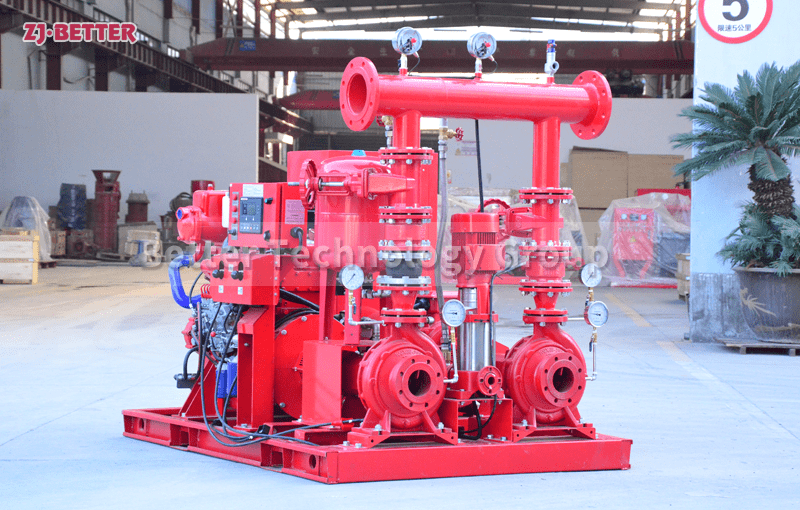

DJ Fire Pump Set

XBC series diesel engine fire-fighting pump group is a new-style fire-fighting equipment (“equipment” thereafter) developed by this Co. in accordance with GB6245-98 “Performance Requirement and Testing Method of Fire-fighting Pumps” and NFPA20 “Installation of Centrifugal Fire-fighting Pumps” etc. standards and, upon the

fitted fire-fighting pumps (single-stage single-suction type, single-stage double-suction type and sectional multistage type), can be divided into XBC-IS, XBC-S and XBC-D three sub series. The equipment has a wide range of pressure and temperature and can be used for almost every occasion necessary for fire-fighting. The diesel engine fitted with the equipment is an excellent product domestic or imported, features good starting performance, strong overload capacity, compact structure, easy maintenance and use and high degree of automation. The equipment is really a fire-fighting one advanced and reliable in performance. The reasonable use and serious maintenance of the fire pump is the most important prerequisite for ensuring the normal and reliable operation of the pump, giving full play to the emergency function and prolonging the service life. In order to make the pump operator familiar with its structural characteristics, grasp the use and maintenance methods, and make good use of the pump, we have prepared this manual for the operator reference

XBC series diesel engine fire-fighting pump group is a new-style fire-fighting equipment (“equipment” thereafter) developed by this Co. in accordance with GB6245-98 “Performance Requirement and Testing Method of Fire-fighting Pumps” and NFPA20 “Installation of Centrifugal Fire-fighting Pumps” etc. standards and, upon the

fitted fire-fighting pumps (single-stage single-suction type, single-stage double-suction type and sectional multistage type), can be divided into XBC-IS, XBC-S and XBC-D three sub series. The equipment has a wide range of pressure and temperature and can be used for almost every occasion necessary for fire-fighting. The diesel engine fitted with the equipment is an excellent product domestic or imported, features good starting performance, strong overload capacity, compact structure, easy maintenance and use and high degree of automation. The equipment is really a fire-fighting one advanced and reliable in performance. The reasonable use and serious maintenance of the fire pump is the most important prerequisite for ensuring the normal and reliable operation of the pump, giving full play to the emergency function and prolonging the service life. In order to make the pump operator familiar with its structural characteristics, grasp the use and maintenance methods, and make good use of the pump, we have prepared this manual for the operator reference