DJ Fire Pump

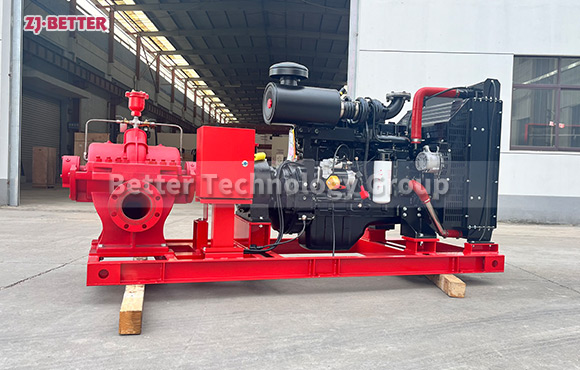

1. Diesel pump: the flow rate is the same as that of the electric pump. It connects pump sets with highly elastic couplings or universal joints.

2. jockey pump: vertical, small flow, higher lift than electric or diesel pumps.

3. Control panel: Automatically control the water pump with overload and overcurrent protection.

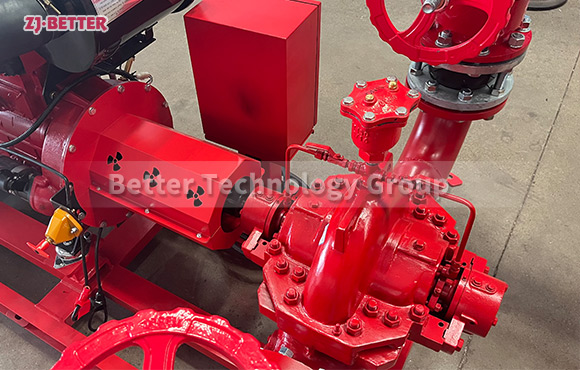

4. Accessories: suction pipe, discharge pipe with flange, battery, gate valve, check valve, flexible expansion joint, pressure switch, pressure gauge, base, etc.

The main pump can be an end suction pump, a split pump, a multi-stage pump, and the standard configuration is stainless steel, cast iron and bronze.

Automatic diesel pump unit: diesel water pump, stabilizer pump, steel structure base, (water heater), battery, connecting line, gate valve, check valve, flexible joint, automatic control panel.

When the pressure drops below the set point, the jockey starts running according to the signal from the pressure switch and continues to run for 10 minutes until the system pressure reaches the set point.

The Fire Pump Control Panel is the brain of the pump system, designed to control and monitor the operation of the diesel engine and the racehorse pump drive, and compose the pump for manual and automatic modes, as well as switch the pump drive on/off under specific conditions. Fire Pump Series Controllers are delivered pre-wired, tested and ready for immediate use.

This fire pump set can be used in fire hose and fire hose reel systems, fire sprinkler systems, fire water monitoring systems, fire alarm systems and fire hydrant systems.