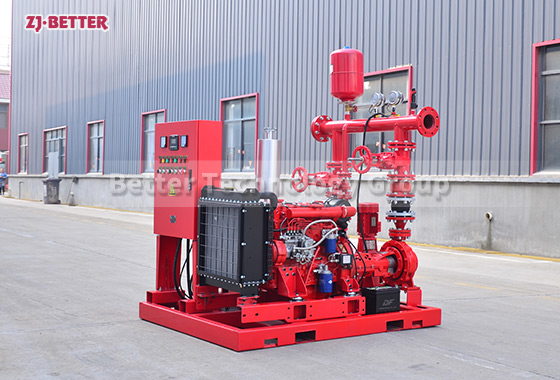

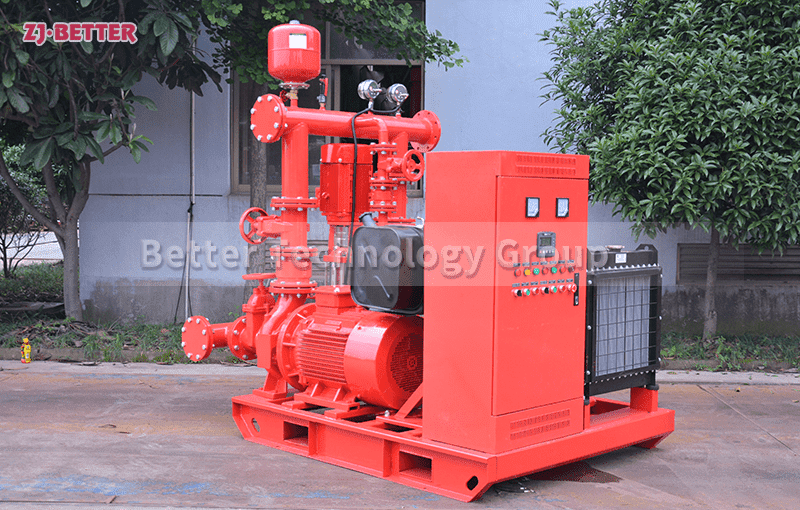

Dual-Drive Fire Pump Unit – Ultimate Backup for Emergency Outages

In critical moments, a stable water supply is the lifeline of fire safety. This dual-drive fire pump system, equipped with both a diesel engine and an electric motor, ensures uninterrupted water pressure even during power outages or emergencies. With its compact structure and space-saving design, the unit offers quick modular installation and is ideal for high-rise buildings, underground parking garages, industrial facilities, and petrochemical storage areas where system reliability is paramount.

The system features an intelligent control panel with automatic power source switching, one-click start/stop operation, and real-time status monitoring—minimizing the need for manual intervention. Even under extreme conditions, this system delivers fast response and consistent performance, making it an essential part of any modern fire protection setup.

As a professional manufacturer specializing in the development and production of fire pump equipment, we are driven by technological innovation and dedicated to delivering high-efficiency, high-reliability fire pump solutions to customers worldwide. Our product range includes diesel engine fire pumps, electric fire pumps, pressure-maintaining systems, and constant-pressure water supply units, widely used in commercial buildings, industrial plants, municipal projects, and petrochemical facilities.

Equipped with advanced production lines and strict quality control processes, our facility ensures that every product meets international fire safety standards from design to delivery. With outstanding performance and proven reliability, our systems are trusted by clients across the globe.