Easy to use for diesel engine fire pumps

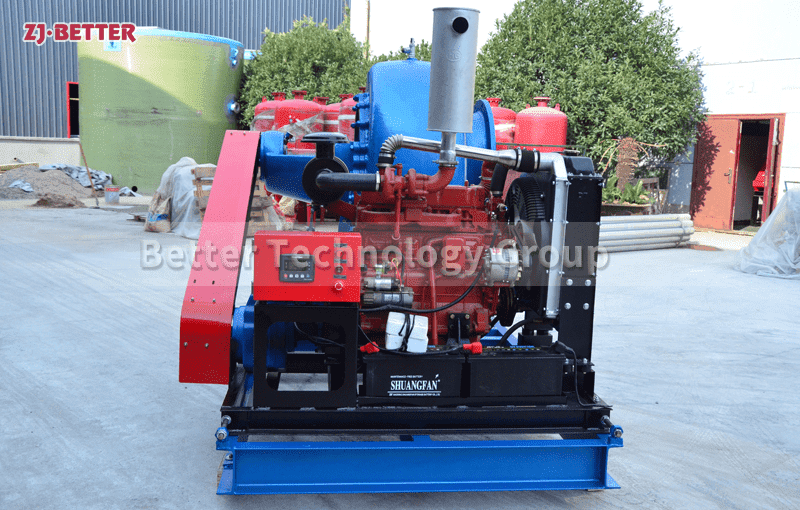

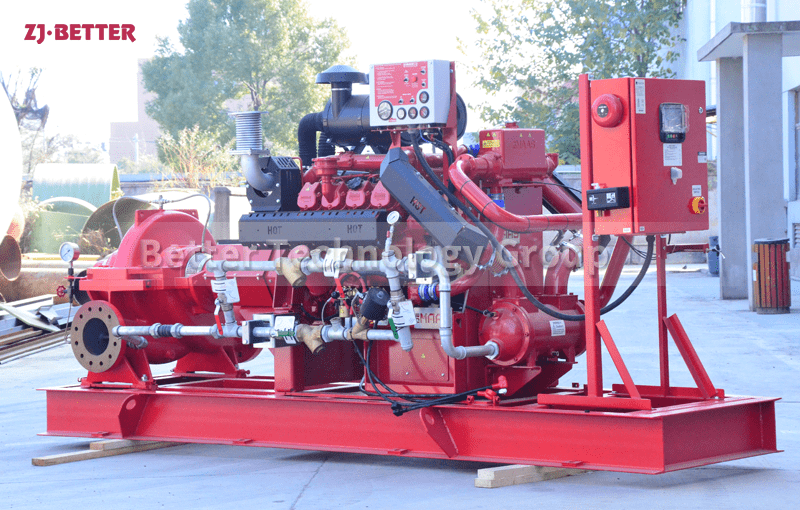

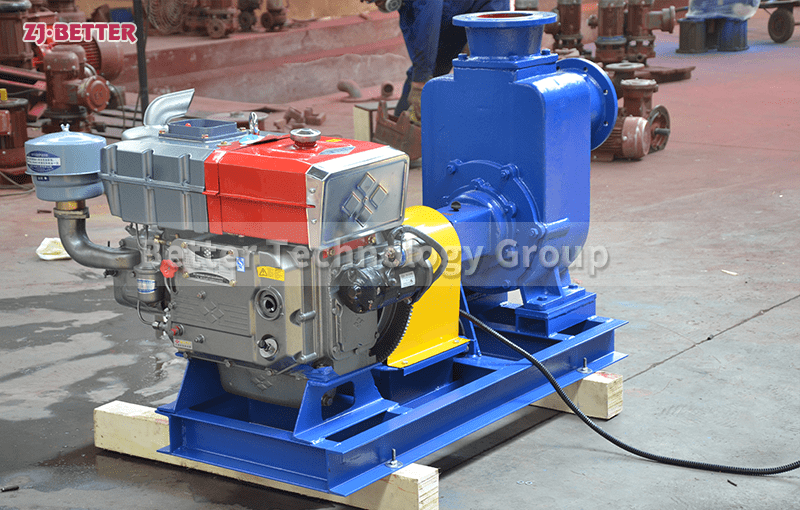

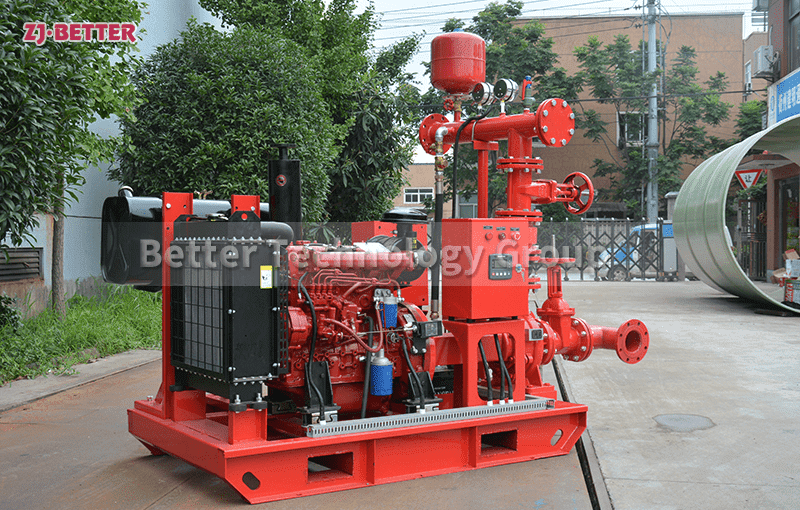

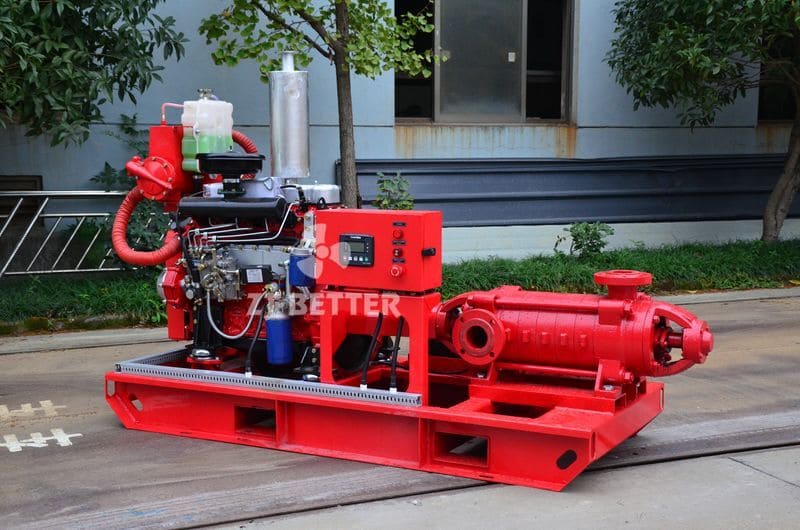

As a common necessary facility, diesel engine fire pumps are automatically started when the fire signal is coming and the electric water pump failure or the power supply is disconnected. The diesel engine fire pump and the electrical instrument are installed together, with complete functions, compact structure, automatic alarm, accepting the start signal, and can automatically complete the startup program and fast full load operation. It is enough to ensure that the diesel engine fire pump is started at low temperature environments. The entire system of diesel engine fire pump is safe and reliable, and it is convenient to use.

After receiving the fire/pipe network pressure/power outage/other startup signals, the diesel engine fire pump can automatically start and enter the full load within 5 seconds. The battery can be automatically charged by the main power or diesel charging motor to ensure the smooth start of the equipment; the diesel engine low oil pressure, high water temperature and other faults such as automatic alarm protection, speed alarm stop; the diesel engine fire pump is in a heat -standing state to ensure emergency work. The diesel engine fire pump uses the direct connection technology of diesel engine and water pump. Through the elastic coupling, the fault point is reduced, which greatly shortens the start time of the unit and improves the reliability and emergency performance of the unit.