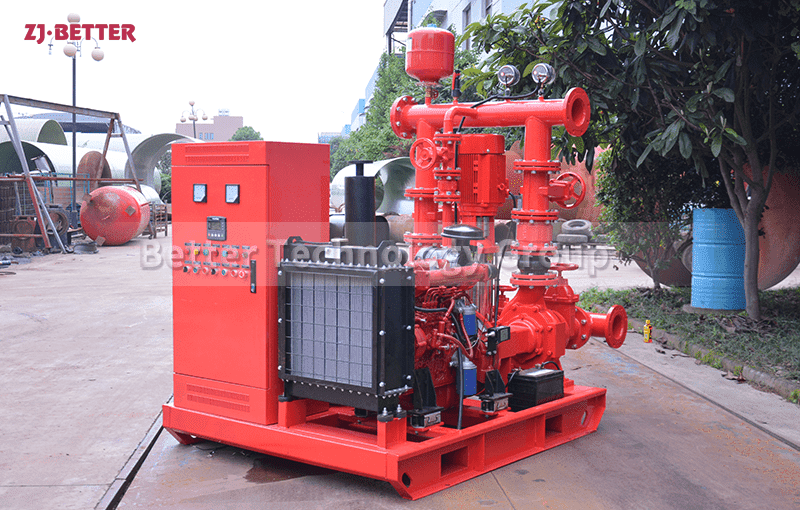

EDJ Fire Pump System: Smart, Reliable Fire Water Supply Solution

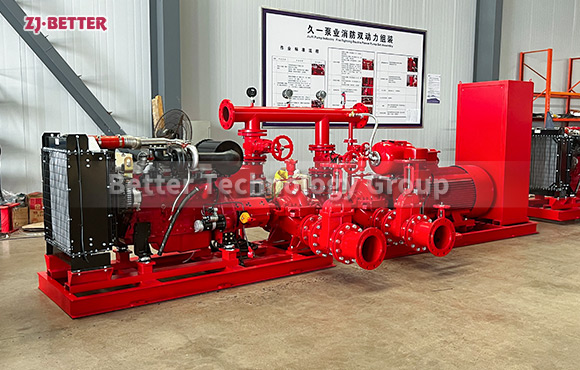

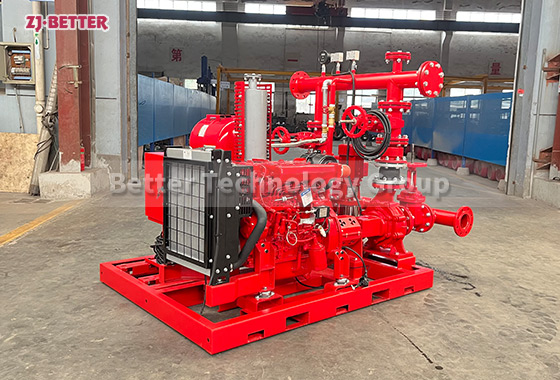

The EDJ Fire Pump system consists of diesel engine fire pumps, electric pump units, and pressure stabilizing pumps, creating an intelligent automatic fire water supply system. Our electric pump units come in various models, including single-stage pumps, horizontal split-case pumps, end-suction pumps, and multi-stage pumps, constructed with cast iron or stainless steel and equipped with efficient copper impellers for exceptional performance.

Whether it’s for buildings, factories, or warehouses, the EDJ fire pump system provides outstanding performance and reliability for your fire protection system, ensuring safety and security during fire emergencies!

Product Features:

1. Reliable water source assurance: The EDJ fire pump system provides a more reliable way to ensure water safety during fire incidents, guaranteeing the proper functioning of the fire protection system.

2. Dual-power automatic switching: During normal mains power supply, the electric pump operates. However, in the event of a power failure where the electric fire pump cannot function properly, the diesel engine fire pump automatically starts to ensure uninterrupted firefighting operations. The diesel engine fire pump is equipped with various automatic functions that meet national standards, ensuring long-term standby readiness and immediate deployment for firefighting tasks.

3. Wide applicability: The dual-power fire water supply equipment is suitable for various locations requiring emergency backup pumps, catering to the diverse firefighting water source needs in different scenarios.