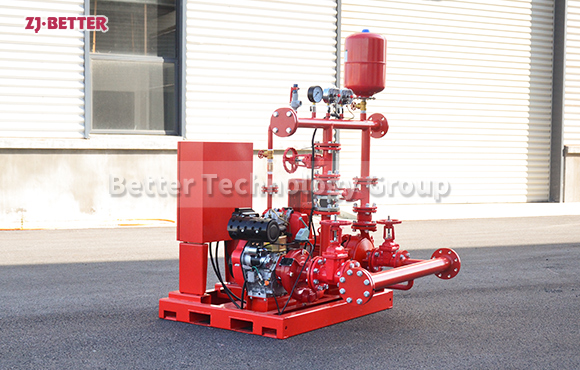

EDJ-ISO Fire Pump Set

EDJ fire pump set is composed of electric pump + diesel pump + jockey pump. The pump set adopts ISO pump,ISO series centrifugal pump is a single-stage single-suction centrifugal pump developed by China Better Technology Co., Ltd. with reference to international similar products using modern fluid mechanics to meet the international standard ISO9908 secondary energy efficiency standard.

This product combines the strengths of similar products in China and abroad and is designed with excellent hydraulic models, therefore, its excellent hydraulic performance and structural features ensure that the user can effectively reduce the operating cost of the pump in various applications.

EDJ fire fighting package set is composed of diesel fire pump, electric pump, jockey pump

1.Electric pump can choose single-stage pump, horizontal split case pump, end suction pump, multistage centrifugal pump, vertical turbine pump which are made of cast iron or stainless steel. Regarding to the impeller, we also could choose the bronze impeller.

2.Diesel fire pump, the flow is same as the electric pump. The diesel engine is combined by high elastic coupling or universal joint connection. The diesel fire set also includes fuel tank, water tank, fan, control panel and other components.

3.Jockey pump which is horizontal or vertical. Normally, it has the characteristics of small flow and higher head (more10-15m head than the electric pump and diesel pump)

4.Control panel. There are some advantages as below:Automatic control of electric pump, diesel pump and jockey pump, with overload, over-current protection

5.The accessories have check valve, gate valve, air pressure tank (0.6 mpa,1.0mpa,1.6mpa), pressure switch, pressure gauge, inlet and discharge pipe, soft joint, flange and common base.