EEJ Fire Pump Set: Built to Last

·UL Standard

Flow:50-3000 GPM

Head: 5-20 Bar (72.5-290 psi)

Speed:740-2900 r/min

·Non-UL Standard

Flow:30-9000 GPM

Head: 3-20 Bar (40-300 psi)

Speed:740-2900 r/min

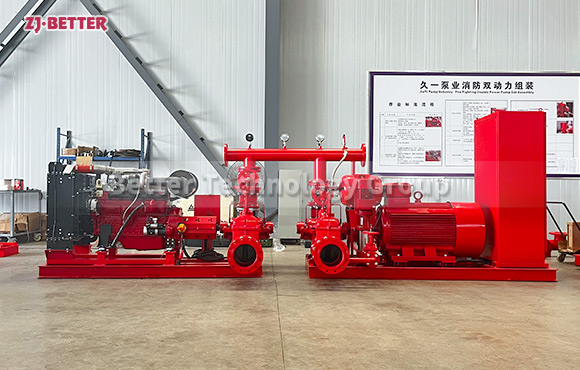

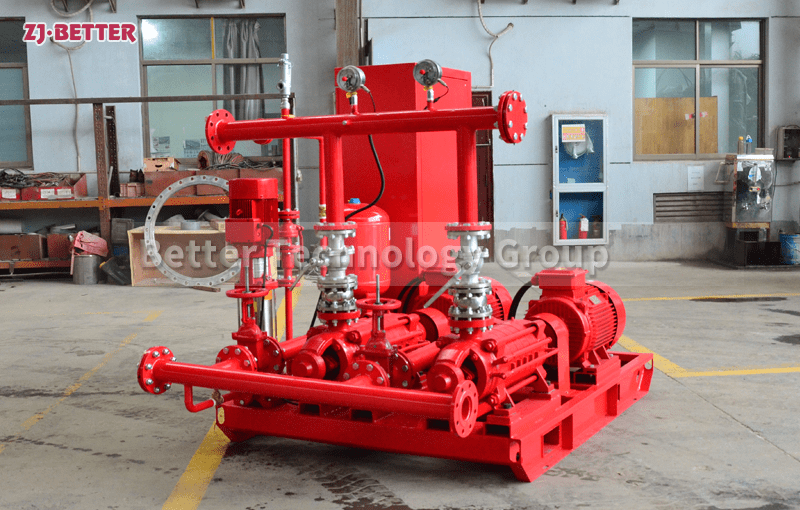

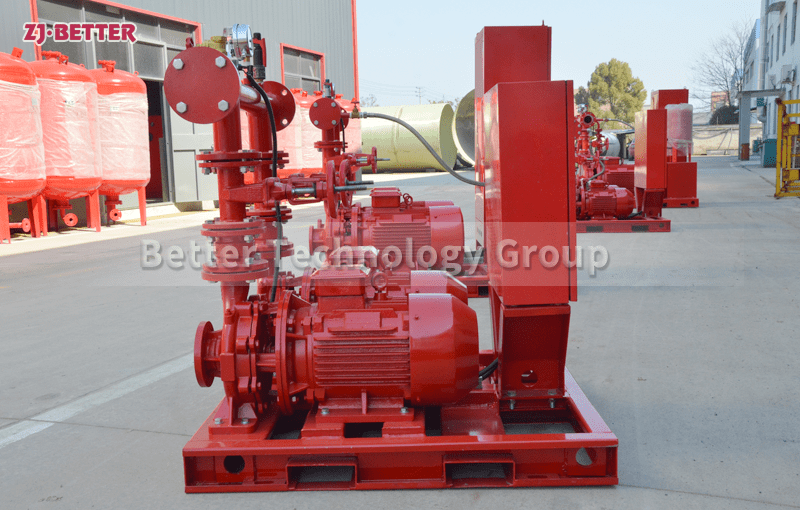

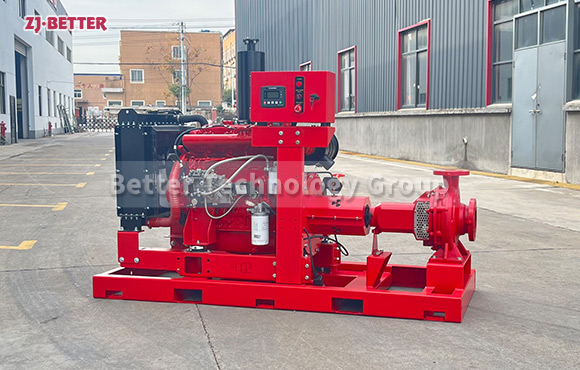

The EEJ Fire Pump System includes two electric pumps and a jockey pump.With exceptional performance and efficiency, the EEJ Fire Pump System delivers high pressure and large flow capacity, enabling rapid and effective fire suppression.

Types of pumps include: End Suction Pump, Split Case Pump, Vertical Inline Pump and Vertical Turbine Pump.

1. Electric motor driven pump, can use single stage pump, horizontal split case pump, end suction pump,multistage pump.

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump.

3. Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, over current protection.

In various fields, our products find applications in large hotels, hospitals, schools, office buildings, supermarkets, commercial residences, subway stations, train stations, airports, various transportation tunnels, petrochemical plants, thermal power plants,oil storage tanks, large warehouses, industrial and mining enterprises, seawater injection, etc.

Overall, the EEJ Fire Pump System offers the advantages of reliable operation, high performance, corrosion resistance, intelligent control, and versatile application. These features make it an exceptional choice for enhancing fire safety and protecting lives and properties in diverse settings.