1. Automatic start: After the diesel engine pump unit receives a fire alarm/pipe network pressure/power failure/or other start-up signals, it can start automatically within 15 seconds and be put into full-load operation;

2. Automatic charging: the battery can be automatically charged by the mains or diesel engine charging motor to ensure the smooth start of the unit;

3. Automatic alarm: automatic alarm protection for diesel engine low oil pressure, high water temperature and other faults, and alarm and stop when the speed is exceeded again;

4. Automatic preheating: keep the diesel engine in a hot standby state to ensure emergency work;

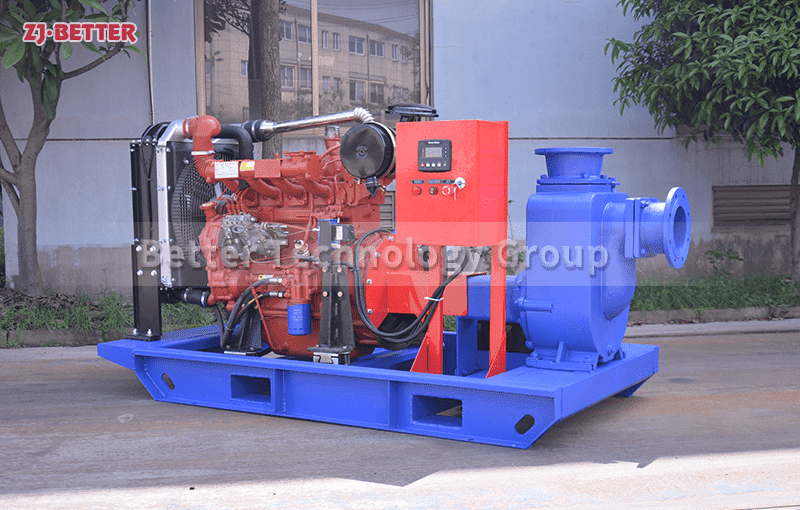

5. Direct connection type: The diesel engine pump unit below 360kw adopts the first domestic direct connection technology between the diesel engine and the water pump through the elastic coupling, which reduces the failure points, greatly shortens the starting time of the unit, and increases the reliability and emergency performance of the unit ;

6. Users can also request to set other alarm outputs (non-standard supply);

7. With telemetry, remote signaling and remote control functions (non-standard supply);

8. The equipment is powered by X6135, 12V135, 4102, 4105, 6102 and other series diesel engines. The diesel engine (with clutch) is connected with the fire pump through a highly elastic coupling to form a fire pump group. Fans, control panels (for automatic units) and other components.

9. When it is an automatic control unit, the split diesel engine automatic control cabinet (programmable) realizes the automatic start, input and automatic switching of the system (the electric pump group is switched to the diesel engine pump group or the diesel engine pump group of this group is switched to another group. Diesel unit), automatic protection (diesel engine overspeed, low oil pressure, high water temperature, three start failures, low oil level, low battery voltage and other alarm shutdown protection) and other functions, and can also interface with the user’s fire center or automatic fire alarm device, Realize remote monitoring.

10. In order to ensure the normal operation of the unit in an environment below 5°C, the unit can be equipped with an AC220V cooling water preheating heating device.

11. Diesel engine fire pump can form an automatic fire water supply system with electric pump group, stabilized pump, etc.

There are two water inlet methods for fire pumps: self-irrigation and suction. According to the requirements of fire protection regulations, it is generally self-irrigation. If the user needs to absorb two kinds of water, according to the requirements of fire protection regulations, it is generally the method of self-irrigation and water diversion. If the user needs to suck up the water inlet system, special instructions are required so that the company can provide an automatic vacuum water diversion device, but the size of the pump set has changed.