Home » Fire Pump Set » EJ fire pump set—manufactured by Better Technology Group Co., Ltd.

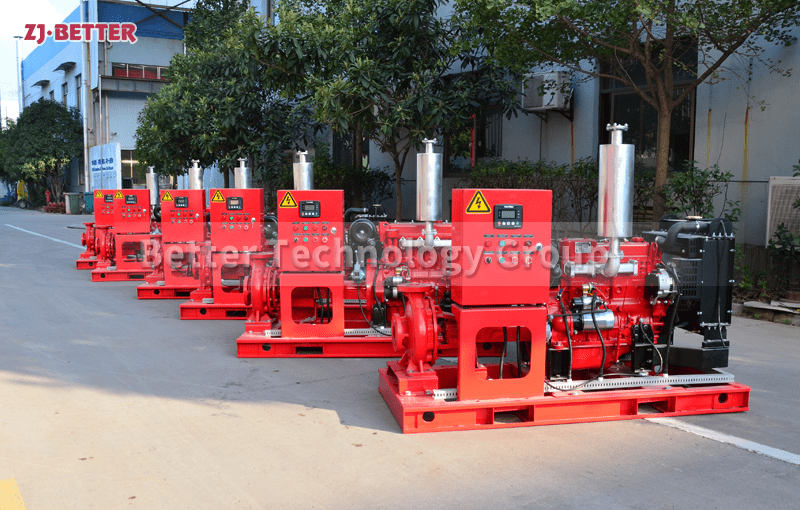

EJ fire pump set—manufactured by Better Technology Group Co., Ltd.

What are the components of the fire pump group

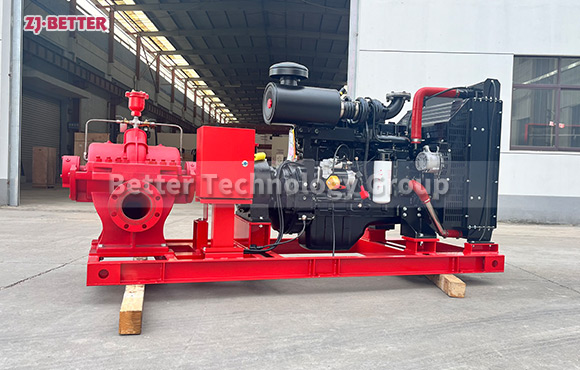

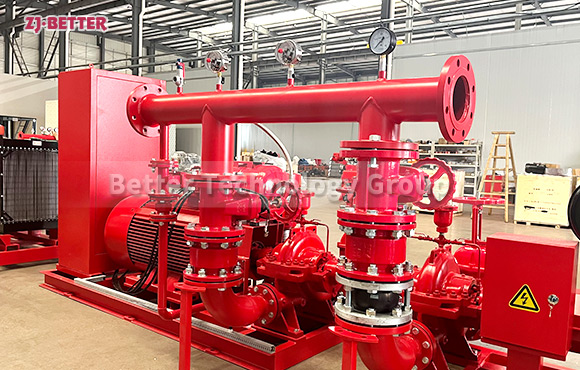

1. Electric pumps: various end suction pumps and split case pump.

2. Jockey pump: vertical, small flow, head higher than electric pump or diesel pump.

3. Control panel: Automatically control the water pump, with overload and overcurrent protection functions.

4. Accessories: suction pipe, discharge pipe with flange, battery, gate valve, check valve, expansion joint, pressure switch, pressure gauge, base, etc.

Contact US

Get Price

Share:

Content

- Electric pump, can use single stage pump, horizontal split case pump, end suction pump, multistage pump, material can be cast iron, stainless steel, and bronze impeller

- Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing :cast iron ,shaft and impeller SS304

- 3. Control panel: Auto Control of electric pump, and Jockey Pump with overload, over current protection.

Inquiry

More Fire Pump Set