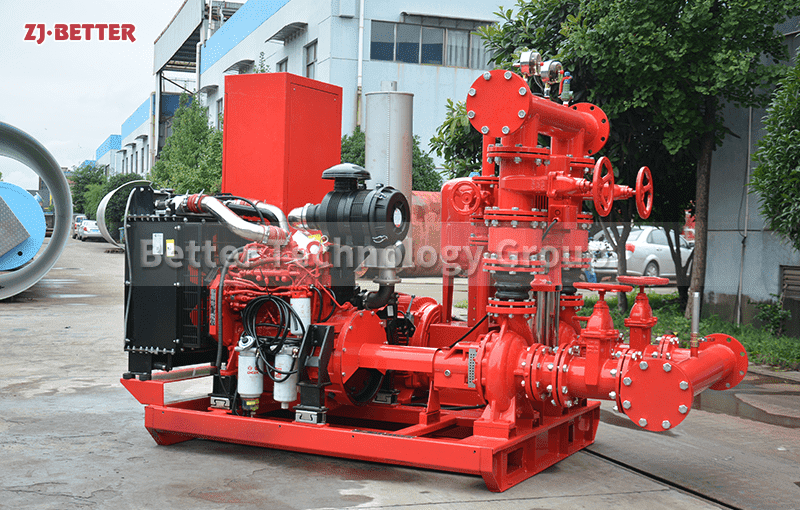

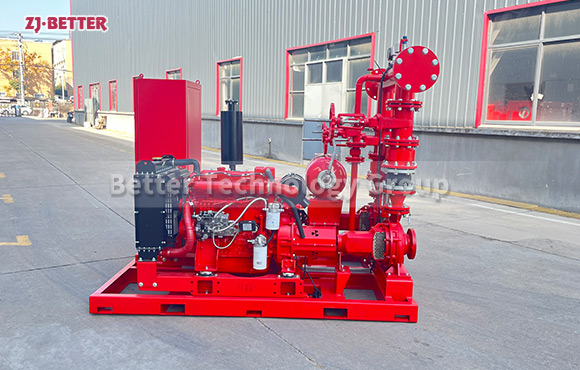

Electric diesel standard fire pump set for emergency use

Diesel engine fire pump group is a new type of fire fighting equipment (referred to as equipment) developed by the company in strict accordance with the national standard GB6245-2006 “Fire Pump” and the American Fire Protection Association Standard NEPA20 “Installation of Centrifugal Fire Pump”. The flow range is wide, and its application almost meets all kinds of occasions required for fire protection.

The diesel engines equipped with the equipment are made of domestic or imported high-quality products. They have the characteristics of good starting characteristics, strong overload capacity, compact structure, easy maintenance and simple use, and high degree of automation. It is an advanced and reliable fire fighting equipment.

1. The first fire pump is used in a well-ventilated place, so it is more conducive to heat and reduce the temperature of the motor. Otherwise, if it runs for a long time, it is easy to burn out the motor. In addition to carefully checking the water stored in the fire pump before starting, it will not only affect their self-priming performance, but also easily burn the shaft seal components.

2. Before starting, check whether the fire pump can work normally and whether there is any jamming fault; whether the position information of the impeller is normal; whether the cable and cable connection plug are broken, scratched or broken, etc.

3. When the fire pump fails, it cannot be disassembled by itself. Because many people don’t know where the fault is causing random disassembly, which can also damage the original good parts.