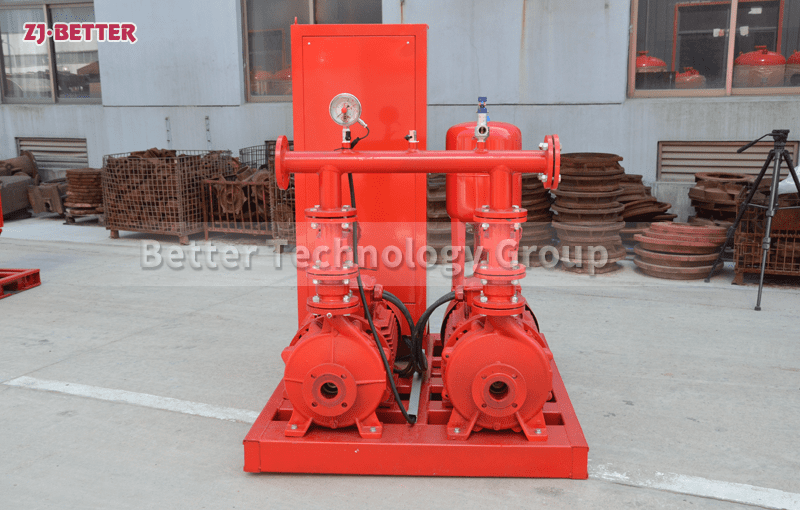

Electric fire pump set is easy to operate and maintain

Electric fire pumps are driven by electric motors, and are divided into horizontal, vertical and many other structural varieties. The electric fire pump set has a small footprint, light weight, low noise, and good start-up and operation performance. Although electric fire pumps have the advantages of simple operation and maintenance, most fire protection system design specifications stipulate that when electric fire pumps are used, they should have the conditions for dual-circuit power supply, and diesel engine fire pumps are usually used as backup pumps.

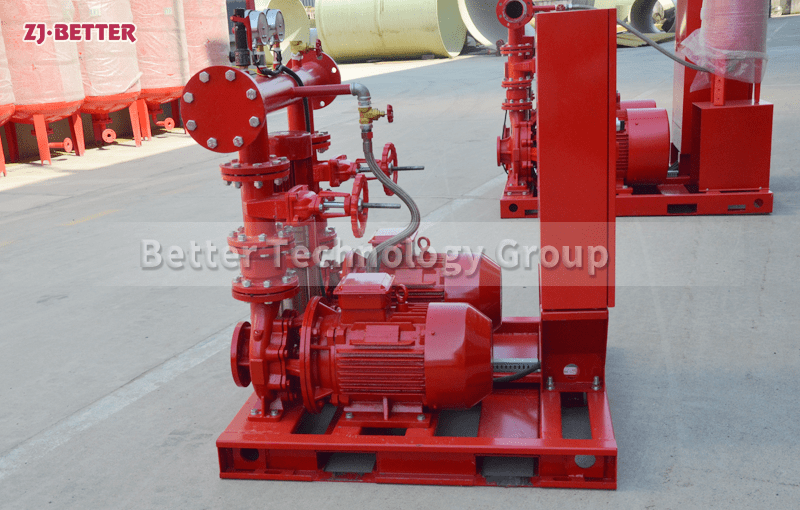

The electric fire pump set is mainly suitable for fire protection engineering of iron and steel, metallurgy, electric power, petroleum, chemical industry, construction, port and other operations, emergency water supply for blast furnace, continuous casting, converter and other accidents, power plant emergency water supply for power failure, nuclear reactor safety protection cooling water supply, and Other water supply projects requiring automatic control.

It mainly transports water without solid particles or liquid with a viscosity similar to water. If the medium transported by the user contains acid or alkali, it should be clarified with the company’s sales when ordering. The temperature of the transported medium is 0°C~+80°C. If appropriate cooling measures are adopted, the medium with a higher temperature can be transported.