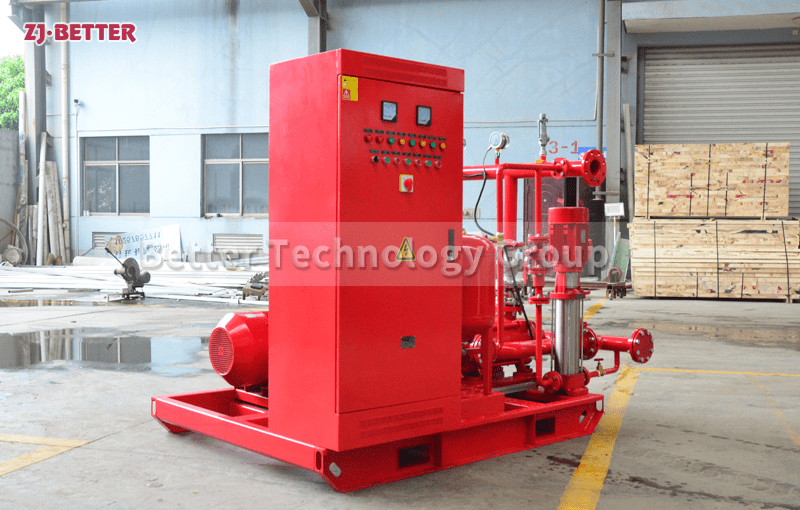

Electric fire pump set is easy to operate

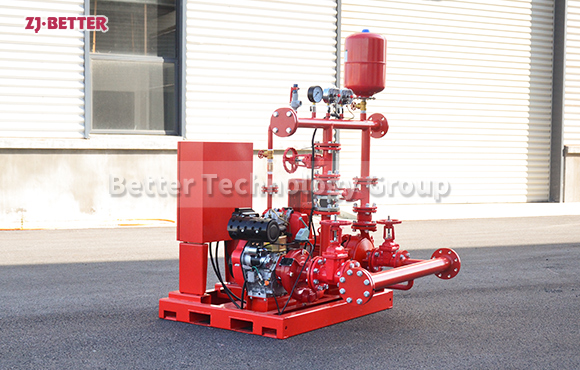

The motor fire pump set is a fire pump powered by an electric motor, and generally consists of a group of fire pumps, motors, control cabinets and auxiliary devices. Because the electric motor fire pump set is composed of these parts, it forms a powerful fire protection and power effect, and provides a strong water source support for various fire hydrant systems and sprinkler systems in the building.

1. Electric motor fire pumps are driven by electric motors and have many different structures, such as horizontal and vertical.

2. The electric motor fire pump set occupies a small area, is light in weight, low in noise, and has good starting and running performance.

3. Although the electric motor fire pump has the advantages of simple operation and maintenance, most of the design specifications of the fire protection system stipulate that when using the electric motor fire pump group, it should have the condition of double circuit power supply, and usually should have the diesel engine fire pump group as a backup pump Group.