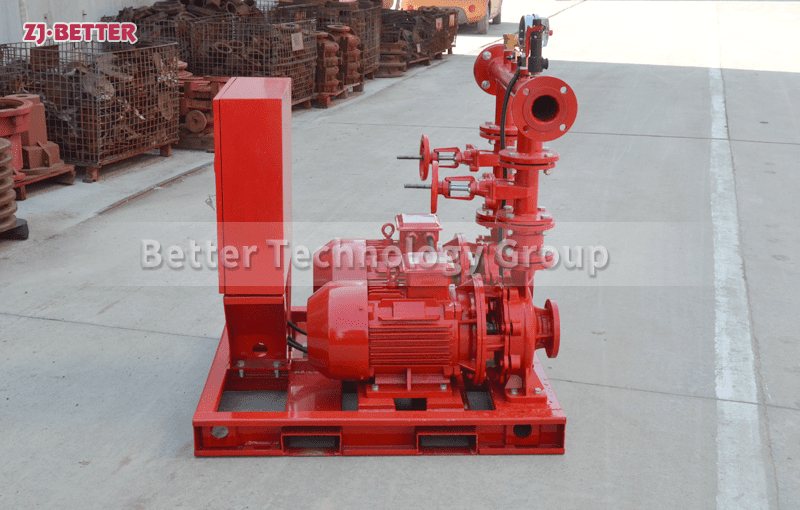

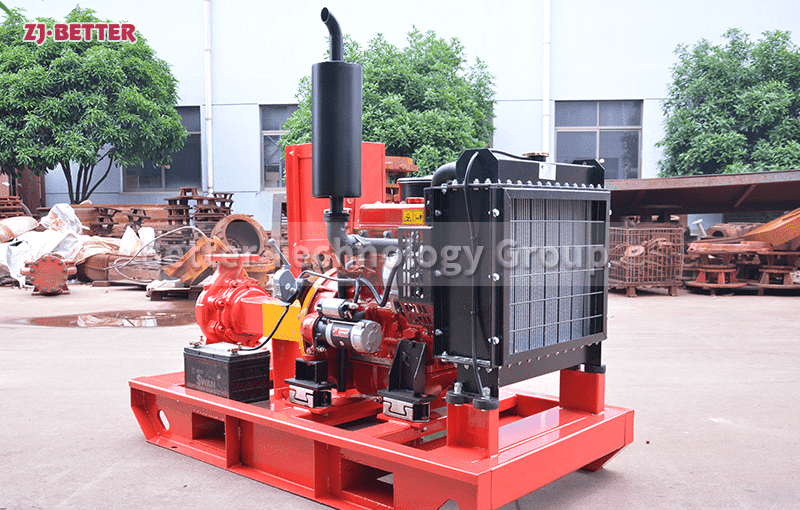

Electric fire pump set is used in fire department and other departments

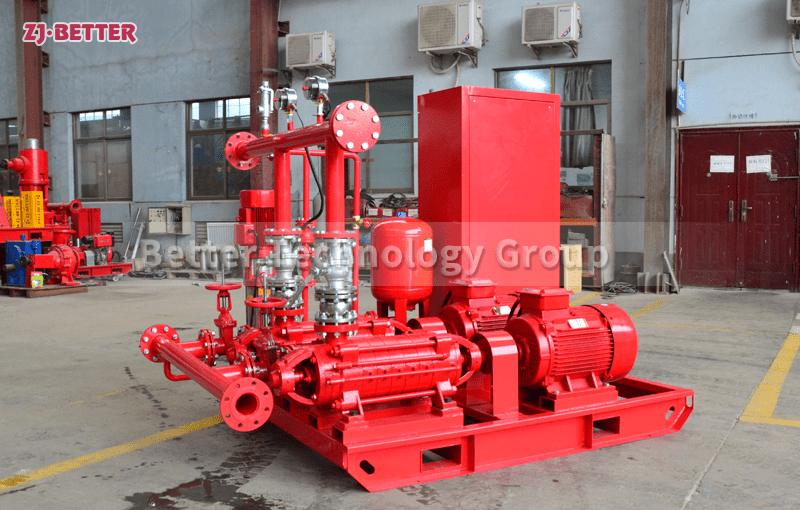

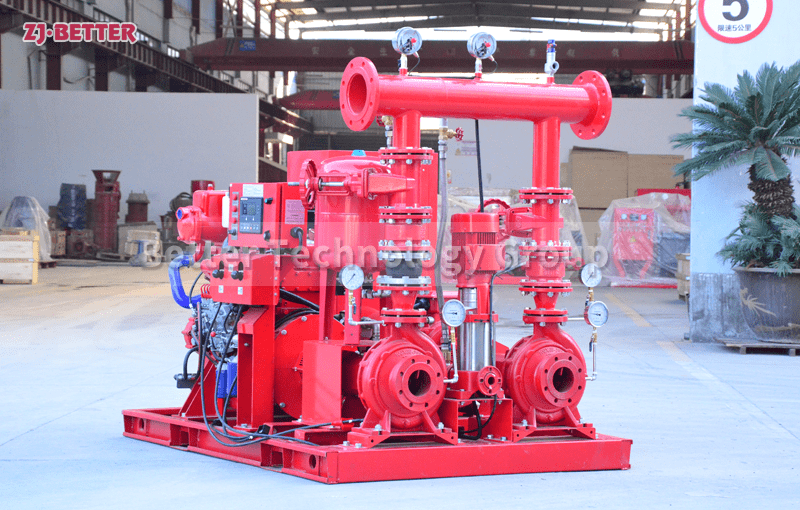

The current use of fire pumps is still relatively important. As the name suggests, fire pumps are pumps used for fire protection. The fire pumps we use now are all imported from abroad. Its performance mainly includes three aspects, sealing, no leakage, and corrosion resistance. Because of the particularity of its use, its requirements are relatively strict in terms of material selection and production. Considering many aspects, the performance and technical conditions of the fire pump meet the requirements of the “Fire Pump Performance and Test Methods” standard.

A variety of electric fire pumps are widely used in environmental protection water treatment and fire protection departments. They can pump and press various liquids in different environments to create leak-free workshops and factories. They are more suitable fire-fighting tools under environmental protection conditions. one. In fact, the types of all pumps are similar, but they are different in terms of development and flow. The choice of fire pump can be selected according to his fire protection public welfare and suction requirements.

In fact, the main function of the fire pump is to use it for fire protection. Environmental protection can pump liquid in a leak-free way in different environmental locations to ensure environmental pollution. Because of its special characteristics, it is favored by many factories.