Electric fire pump set with wide flow range

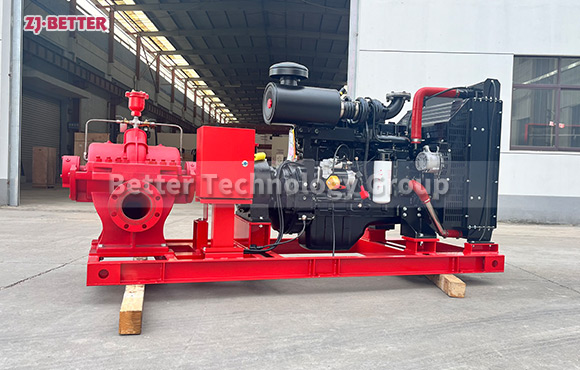

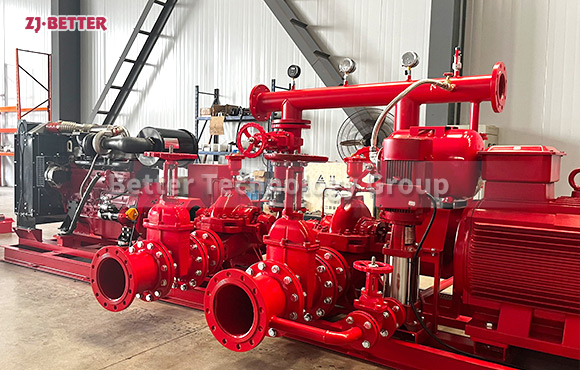

The motor fire pump unit is powered by an electric motor to drive the fire pump and output pressure water for fire fighting. The pump unit is mainly composed of a motor, a water pump, a transmission device, a common base and an instrument table. The starter cabinet is installed near the pump unit for starting the motor.

The electric fire pump set has the advantages of quick start, reliable water diversion, stable operation, high degree of automation, wide range of pressure and flow, etc. It is an advanced and reliable fixed fire-fighting equipment.

The electric fire pump set is a new type of fire protection equipment developed by our factory in strict accordance with GB6245-2006 “Fire Pump Performance Requirements and Test Methods” and with reference to the NFPA20 standard of the American Fire Protection Association. It is mainly used in petroleum, chemical, natural gas, power plants, and textiles. Fire water supply and foam fire extinguishing systems in industries such as cotton and linen, wharves, gas stations, storage, high-rise buildings, etc.