Electric fire pumps are used in various water environments

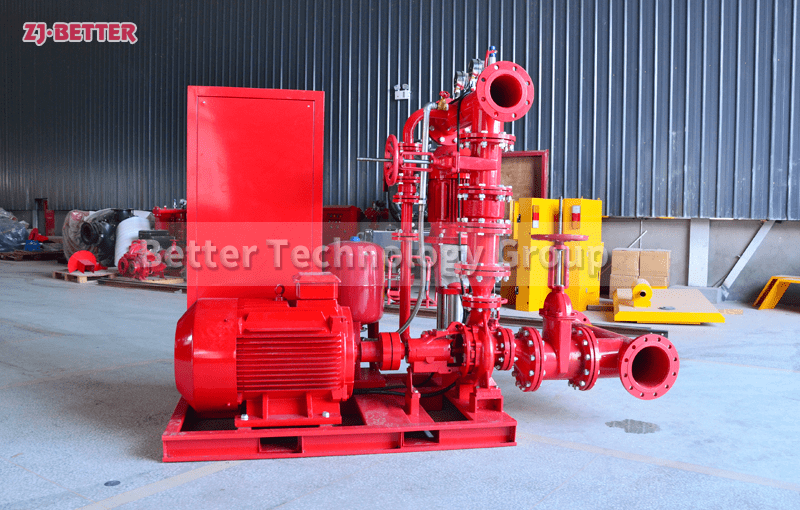

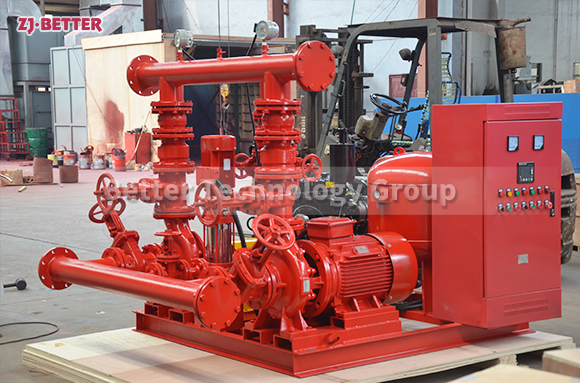

Electric fire pumps are used in various water environments, not only to meet the general water supply but also to be a good helper for fire-fighting water. The electric fire pump is manufactured with good structure and workmanship. It has a wide range of performance, and is easy to use and operate for a long time. The motor fire pump is aimed at various fire water environments, so the selection should also be based on the actual demand environment, performance parameters, etc.

There are many types of electric fire pump sets, including long-axis fire pumps, vertical single-stage or multi-stage fire pumps, horizontal fire pumps, etc., and are selected based on the installation environment and performance requirements (pressurization/stabilization, etc.). Fire pumps occupy an important position in both life and production, requiring more but stable performance. As long as you choose a suitable fire pump manufacturer to ensure the quality of the pump and the correct selection of the pump, there will be fewer troubles for daily use. There are two types of seals for electric fire pump sets: packing seal and mechanical seal. Different forms can be used in different environments. The difficulty of manufacturing and material selection lead to different prices. For most users, the suitable fire pump selection material is very good. High-quality equipment does not need to exceed the requirements of good materials and oversized models, otherwise it will easily cause many failures and difficult maintenance.