Emergency Response Made Easy with Mobile Pump Trucks

Flow:25-10000 GPM

Head:80-360m < 25 Bar < 362.5 psi

Speed:1500-1800 r/min

Frequency:50 or 60 HZ

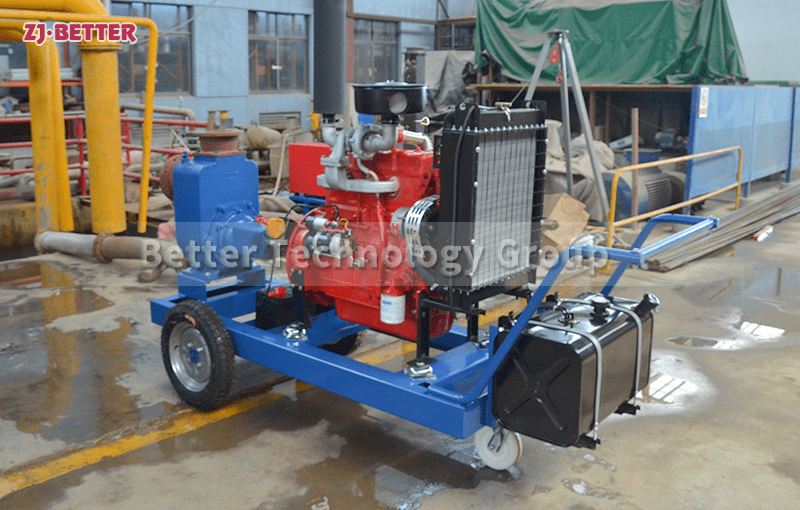

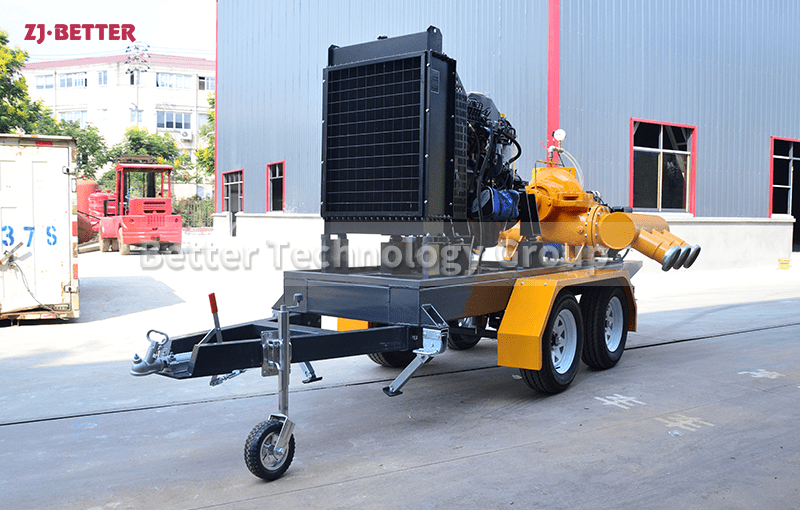

A mobile pump truck tailored for industrial emergencies is a specialized vehicle crucial for addressing crises within industrial settings. Combining mobility, advanced pumping technology, and versatile configurations, it serves as a vital tool for firefighting, emergency water supply, and hazardous substance containment.

A mobile pump truck plays a crucial role in industrial emergencies as a specialized vehicle designed for emergency response within industrial environments. It combines mobility, pump technology, and flexibility to provide firefighting, emergency water supply, and hazardous fluid handling capabilities for industrial facilities. Here’s an introduction to a mobile pump truck used for industrial emergencies:

- Functions and Uses

Firefighting: Industrial facilities often involve hazards such as high temperatures and flammable materials. A mobile pump truck can rapidly provide water supply and pressure to effectively extinguish fires, safeguarding personnel and equipment.

Emergency Water Supply: Interruptions in water supply or sudden incidents can occur in industrial areas. The mobile pump truck can draw water from nearby sources to provide emergency water supply for production facilities.

Leakage Management: Chemical spills and leaks can happen in industrial environments. The mobile pump truck can be utilized to handle hazardous substance leaks, minimizing environmental pollution and health risks.

- Design Features

Powerful Pump System: Mobile pump trucks are typically equipped with efficient pump systems capable of delivering high pressure and flow rates to address different types of fires and emergencies.

Large Capacity Water Tank: These trucks often come with a large water tank to store an ample firefighting water supply, ensuring sustained availability.

Adaptable Configurations: Depending on the industrial setting, mobile pump trucks can be configured with various types of nozzles and accessories to cater to diverse emergency scenarios.

Portability: Despite their size, mobile pump trucks retain a degree of mobility, enabling them to be flexibly deployed to different locations.

Industrial emergency mobile pump trucks play a vital role in securing industrial facilities and minimizing losses. They promptly respond to various emergency scenarios, providing the necessary firefighting and emergency support for industrial environments, ensuring the safety of production facilities and personnel.