Emergency Response Perfected: DJ Dual-Power Fire Pumps

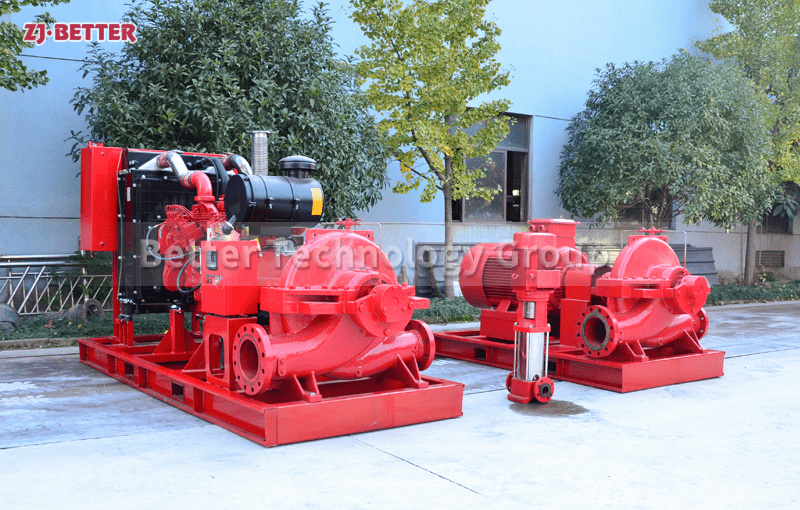

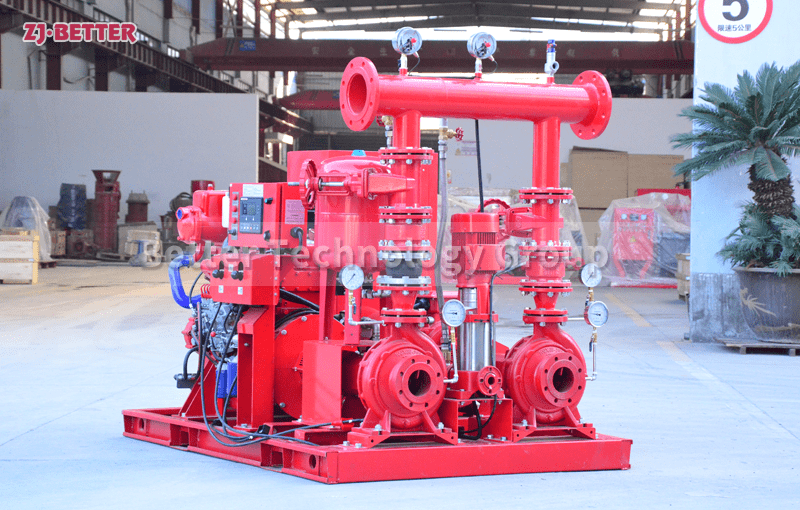

The DJ Fire Pump Set is a combination system consisting of a diesel engine pump and a jockey pump, designed for fire safety in the construction and industrial sectors. This system utilizes the powerful power output of the diesel engine pump, ensuring reliable operation even in the event of a power outage. The jockey pump maintains a constant water pressure, optimizing the performance of the fire suppression system. The DJ Fire Pump Set offers a reliable and efficient solution for prompt response to fire incidents, making it an essential component for protecting property and ensuring occupant safety.

- Powerful Performance: The diesel engine pump delivers robust power output, ensuring the fire pump set operates efficiently during emergencies. Even in the event of a power outage, it can function independently, guaranteeing the continuity of your fire protection system.

- Stable Water Pressure: The jockey pump maintains a constant water pressure, ensuring your fire suppression system operates optimally. It continuously monitors the water pressure and automatically starts to replenish the water source, thereby keeping the system running smoothly.

- Reliability and Durability: The DJ Fire Pump Set is built with high-quality materials and advanced manufacturing techniques, ensuring its durability and reliability. It can withstand harsh environmental conditions and prolonged operation while delivering excellent performance.

- Rapid Response: During a fire incident, time is of the essence. The DJ Fire Pump Set offers quick response capabilities, swiftly starting up and providing a steady water flow to promptly control and extinguish the fire.

By choosing the DJ (Diesel engine pump + Jockey pump) Fire Pump Set, you opt for a reliable, efficient, and secure solution to protect your property and ensure the safety of occupants. Whether for commercial buildings, industrial facilities, or residential areas, it is an indispensable fire safety equipment that offers robust support and protection to your fire protection system.