Excellent performance:The ED Dual-Power Fire Pump Sets

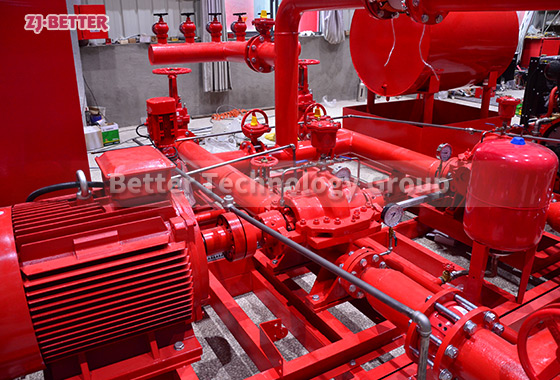

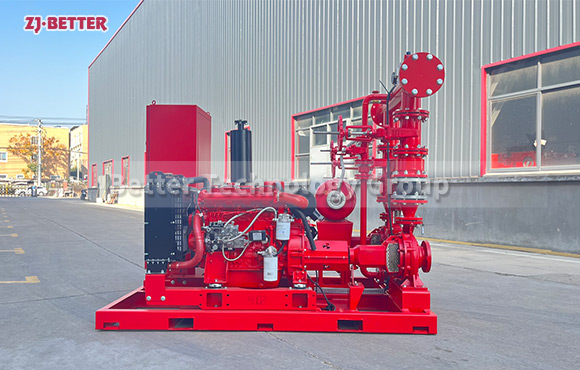

The ED Dual-Power Fire Pump System combines electric and diesel engine pumps to ensure uninterrupted fire protection and a reliable water supply. In the event of power outages or electrical failures, the diesel engine pump seamlessly takes over, guaranteeing continuous operation of the fire protection system. This dual-power configuration offers both reliability and flexibility, providing comprehensive coverage for fire safety needs. With smart controls and automatic switching mechanisms, the transition between electric and diesel engine pumps is seamless, minimizing system downtime. Equipped with advanced safety features, including monitoring and alarm systems, real-time status updates allow for prompt action in case of any irregularities.

Ensure continuous fire protection with the ED Dual-Power Fire Pump System. Combining the reliability of electric and diesel engine pumps, this innovative system guarantees uninterrupted water supply for enhanced safety in critical fire scenarios.

1.Reliable Performance: The ED Dual-Power Fire Pump System incorporates both an electric pump and a diesel engine pump, providing redundancy for uninterrupted operation. In the event of power outages or electrical failures, the diesel engine pump seamlessly takes over, ensuring a reliable water supply to your fire protection system. Trust in this dual-power setup for dependable performance.

2.Efficiency and Flexibility: The electric pump component of the ED Dual-Power Fire Pump System offers efficient operation under normal conditions, providing optimal pressure for your fire suppression system. Meanwhile, the diesel engine pump ensures reliability when electrical power is compromised. This versatile combination ensures comprehensive fire protection coverage.

3.Seamless Transition:With smart controls and automatic switching mechanisms, the transition between the electric and diesel engine pumps is seamless. This ensures a smooth transfer during power disruptions, minimizing system downtime and maximizing its effectiveness. Count on the ED Dual-Power Fire Pump System for uninterrupted fire protection.

4.Enhanced Safety Features: Equipped with advanced safety features, the ED Dual-Power Fire Pump System includes monitoring and alarm systems for real-time status updates. Prompt action can be taken in case of any irregularities, ensuring a responsive fire protection system. Rest assured that your safety is prioritized.

5.Choose the ED Dual-Power Fire Pump System: Elevate your fire protection capabilities with the reliable ED Dual-Power Fire Pump System. With its dual-power redundancy, efficient operation, and seamless transition between electric and diesel engine pumps, it ensures uninterrupted fire protection. Trust this system to safeguard lives and property in critical fire situations.