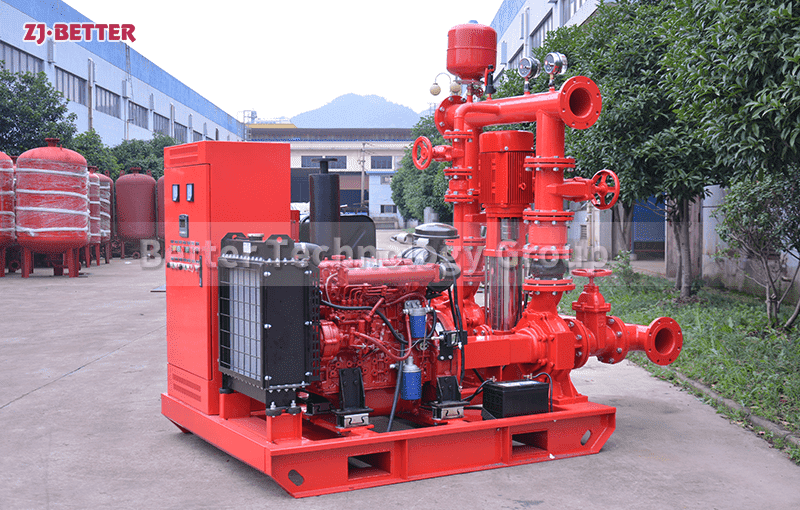

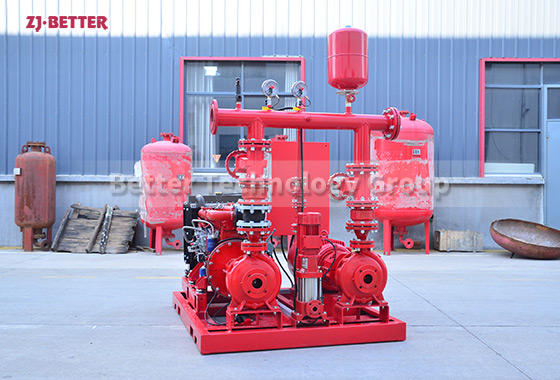

Factory direct sales of efficient and convenient fire pump sets

The fire pump is part of the water supply of the fire sprinkler system and can be powered by electricity or diesel. The inlet of the pump is connected either to a public groundwater supply or to a static water source (e.g. tank, reservoir, lake). The pump supplies water at higher pressure to the sprinkler system risers and hose risers.

Fire pumps generally use three driving forces, including diesel engines, gasoline engines and electric motors. Gasoline engines are commonly used in portable fire pumps and light duty firefighting. Electric motors are the most widely used driving force for fire pumps and are both efficient and convenient.

1. The fire pump is used to ensure the water volume and water pressure of the fire water, which involves personal safety and property protection, and must operate more reliably. It is required that the structure of the pump body is more reasonable, the material is more appropriate, and the reliability is higher.

2. The water supply of the fire pump generally adopts the method of directly supplying water to the fire extinguishing facilities (fire hydrant, sprinkler head) by the water pump. In the initial fire extinguishing or self-checking operation, the water supply is small flow, and the water supply is designed according to the design flow in the fire development stage. When the flow rate-lift curve of the pump is steep, it is easy to generate overpressure during small flow operation, and corresponding technical measures should be taken for this.

3. The fire pump is used for extinguishing fire, and it is required to be fast and timely. The corresponding requirement is that the fire pump has a shorter water diversion time than ordinary life pumps and better starting performance.