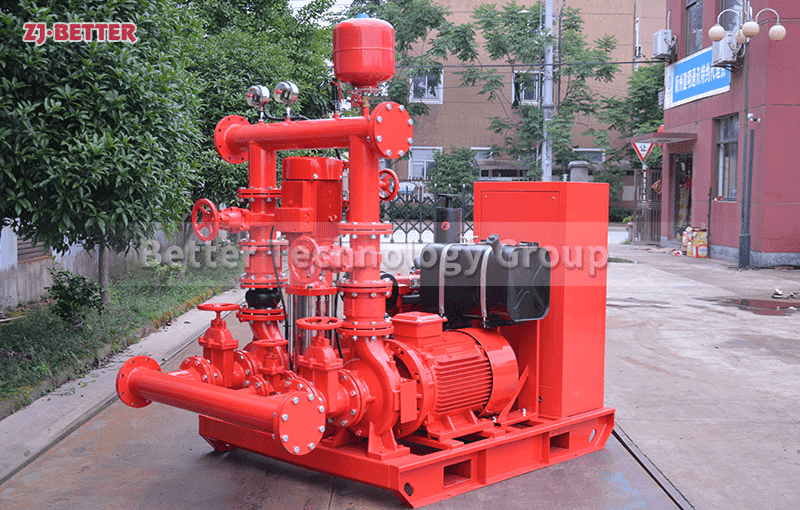

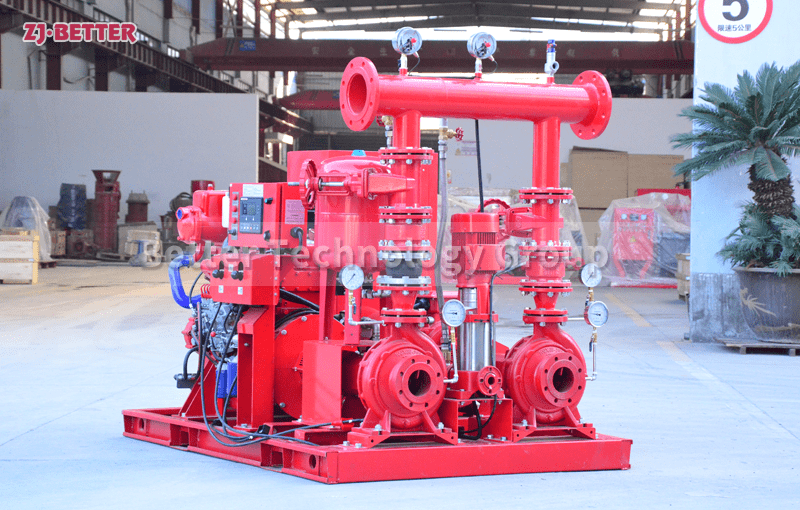

Factory That Manufactures EDJ Fire Pump Equipment

The conventional electric pump is the main pump, the diesel engine pump is the backup pump, and the jockey pump plays a role in the stabilization of the whole system. When the electric pump fails or the mains is cut off, the control cabinet will receive the pressure gauge from the electric contact. When the signal comes, the diesel engine pump will be started within 5 seconds, and the rated working condition will be reached within 20 seconds to ensure the normal operation of the fire extinguishing work.

In general, the equipment is designed to have one duty and one standby function. The main pump runs normally, and the standby pump starts automatically after the main pump fault . The Jockey pump will start and stop based on the pipe pressure, when the electric pump malfunction or mains power, control cabinet will receive signals from the electric contact pressure gauges and start the diesel engine pump in 5 seconds, and achieve the rated conditions in 20 seconds, ensure the normal conduct of fire fighting work.

EDJ has below advantages:

1.Easy to installation: we have completed all the work in our factory, when you receive the EDJ pump to the site, you just need to connect the inlet and outlet to the main road through a flange, the low pipe is the inlet and the high pipe is the outlet.

2. Easy to debugging: The equipment adopts PLC modular design, and personnel with basic circuit knowledge can operate debugging.

3. Reduce installation time: Since the installation steps are relatively simple compared with a single set, the working hours are greatly shortened.

4. Realization of integration: Diesel pump, electric pump, pressure regulator pump, control cabinet and so on are all on the one base. The product adopts mechanization production, has the good quality assurance and the high production efficiency.

5. Space saving: The installation space is greatly saved compared with the traditional on-site installation.

6. Pre-installation of electrical circuits: The power lines and sensor lines between the control panel and each pump have been connected when the product is ready to ship. you only need to connect to the main power supply according to the drawing at the site.