Find a professional manufacturer for fire pumps – ZJBetter

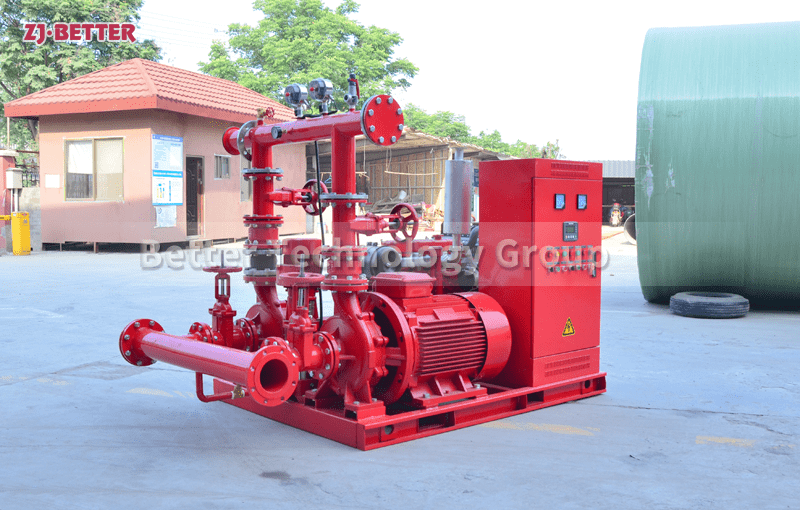

The fire pump is usually equipped with a local control cabinet. The control cabinet does not have a transfer control switch for automatic and manual conversion, but the automatic control loop leaves start and stop contacts, which are connected to the fire alarm system control module. In addition, according to the relevant regulations, the system using the bus linkage control should also be set in the fire control room with buttons that can directly start and stop the pump. When the fire alarm system receives the signal of the fire hydrant start pump button, the control module automatically starts the fire pump and collects its feedback signal.

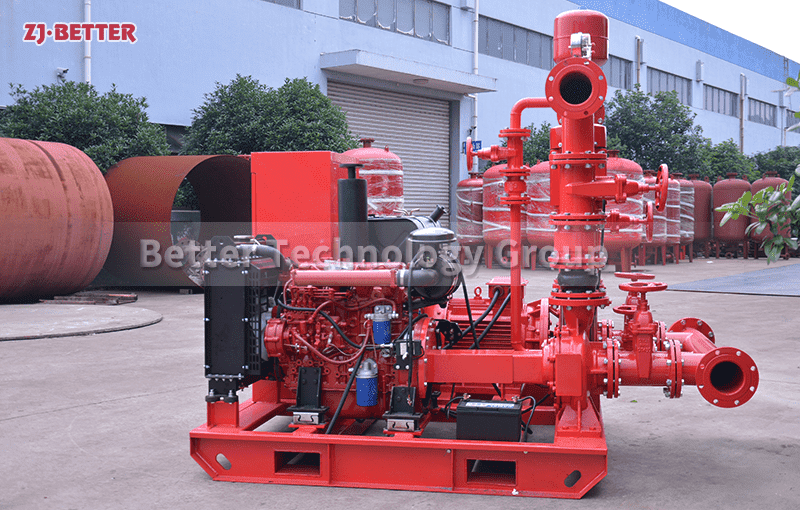

There are many types of fire pumps to deal with more fire water environments. Fire pumps are used in buildings, factories, warehousing and other places, and the performance requirements and quality requirements are different. The commonly used types of fire pumps are vertical electric fire pumps, diesel fire pumps, horizontal single-stage fire pumps, vertical single-stage / multi-stage fire pumps The specific head, flow and power are selected according to different projects.

There are many applications for fire pumps. Different motors are selected according to the flow rate and head size. Commonly used motors include electric motors, diesel engines, etc., and domestic and foreign brands can be matched for application. The fire pump can choose vertical or horizontal structure according to the pipeline requirements, and the head size is also different. Finding a professional pump factory or company can reduce the probability of wrong selection, and also consider the site installation requirements and pipeline design.