Home » Fire Pump Set » Fire Pump Cooling Methods: Preventing Overheating

Fire Pump Cooling Methods: Preventing Overheating

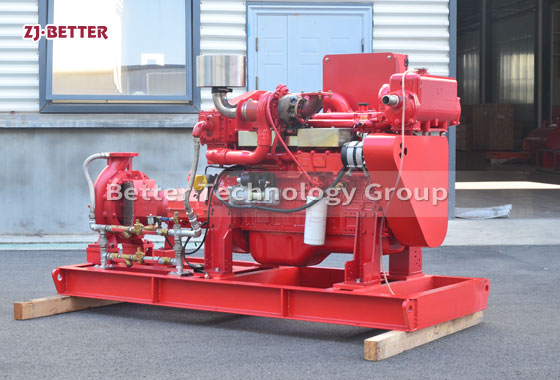

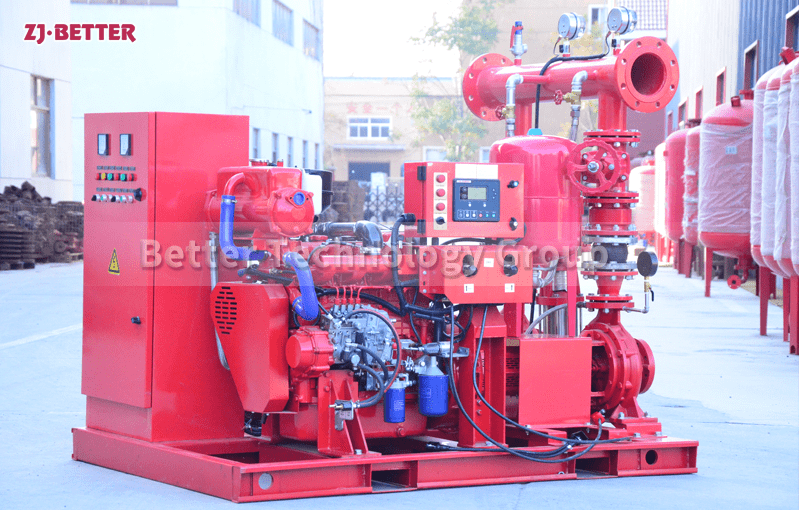

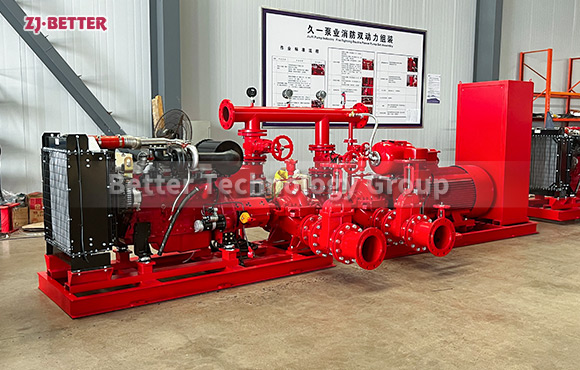

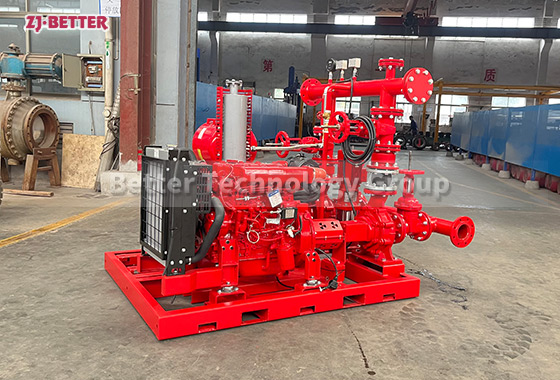

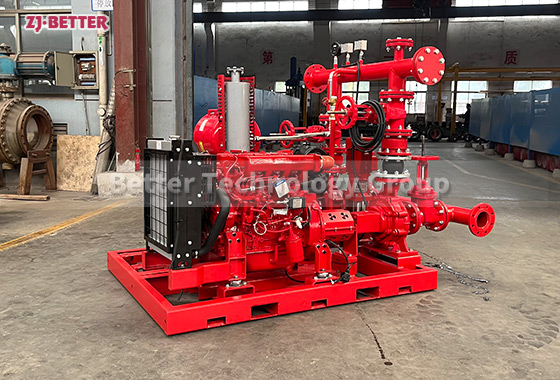

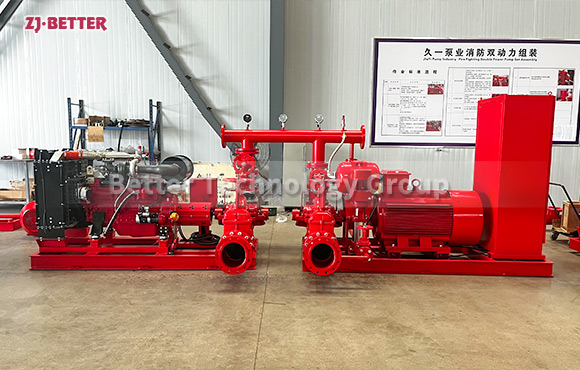

Fire pumps generate heat during operation, and preventing overheating is essential to maintain their efficiency and longevity. This article explores various cooling methods for fire pumps, including air cooling, water cooling, and heat exchangers. It highlights the role of cooling systems in preserving pump performance.

Contact US

Get Price

Share:

Content

Fire pumps generate heat during operation, and preventing overheating is essential to maintain their efficiency and longevity. This article explores various cooling methods for fire pumps, including air cooling, water cooling, and heat exchangers. It highlights the role of cooling systems in preserving pump performance.

Inquiry

More Fire Pump Set