Fire pump installation requirements and maintenance management requirements

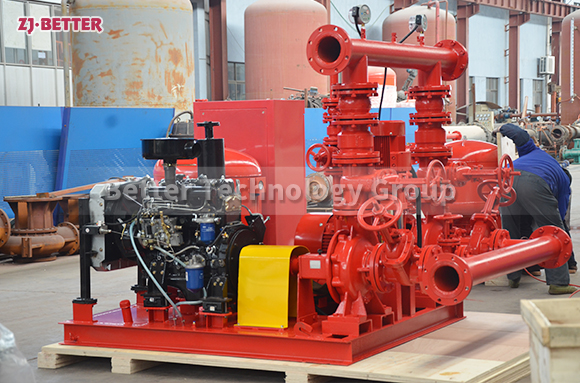

1. The performance of the fire pump should meet the flow and pressure requirements of the fire water supply system.

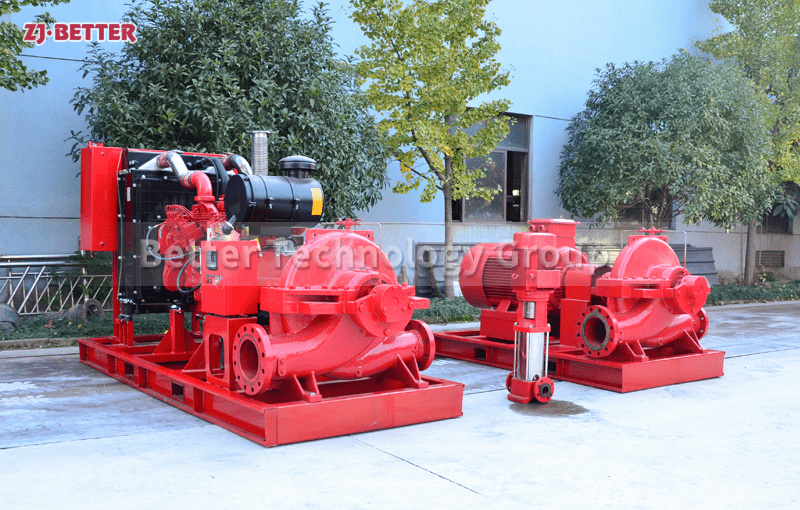

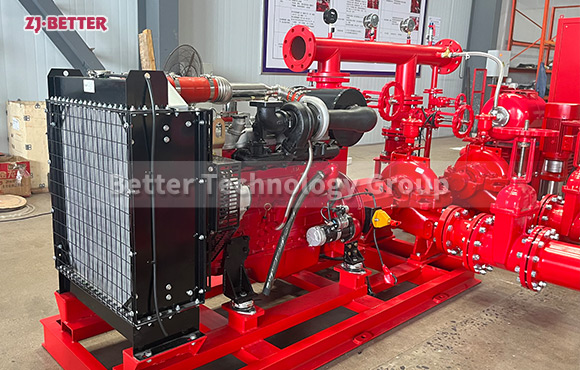

2. The power of the driver equipped with the fire pump should meet the requirements of the power required for operation at any point on the performance curve of the selected pump’s flow and lift.

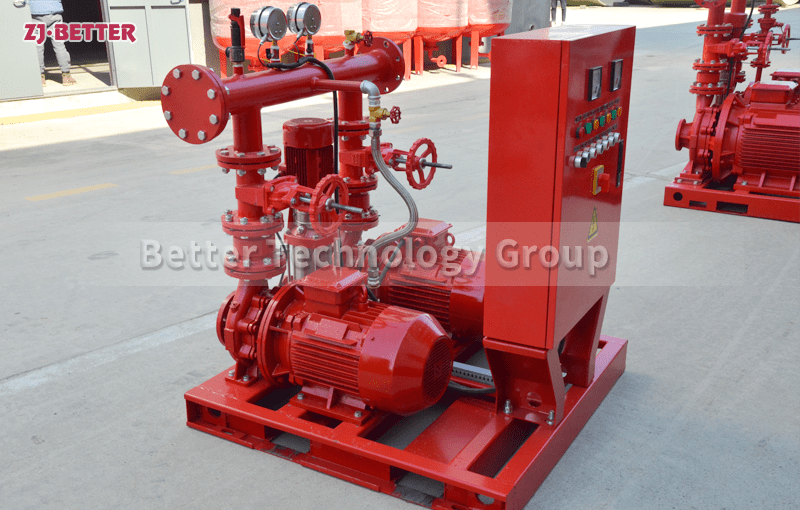

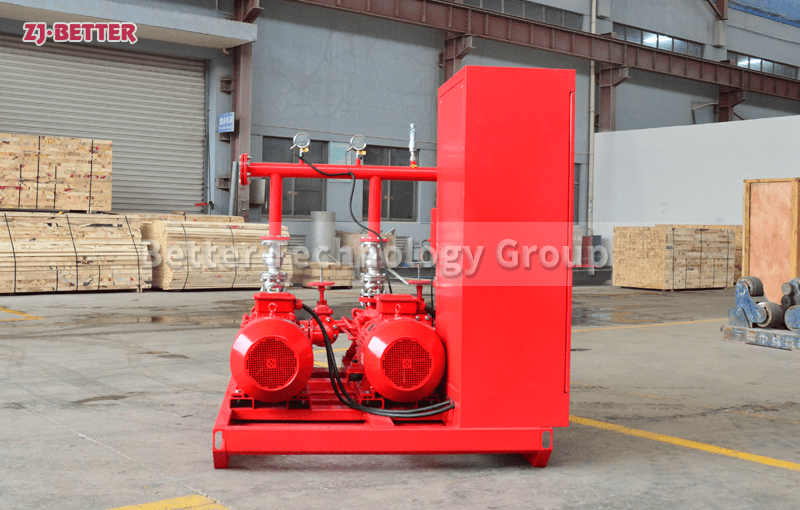

3. When a motor-driven fire pump is used, a dry-installed fire pump with the motor should be selected.

4. The fire pump should be installed dry, and the pump should be placed outside the pool, and the submersible pump cannot be directly placed in the water for water absorption.

1. The fire pump should be started manually once a month, and the power supply should be checked.

2. The fire pump should be automatically started once a week to simulate the automatic control conditions of the fire pump, and the automatic inspection situation should be automatically recorded, and the inspection record should be recorded every month.

3. The electric quantity of the starter battery of the diesel engine fire pump should be tested every day, the oil storage capacity of the oil storage tank should be checked every week, and the diesel engine fire pump should be manually started to run once a month.

4. The output flow and pressure of the fire pump should be tested once a quarter.