Home » Fire Pump Set » Fire Pump Maintenance Knowledge

Fire Pump Maintenance Knowledge

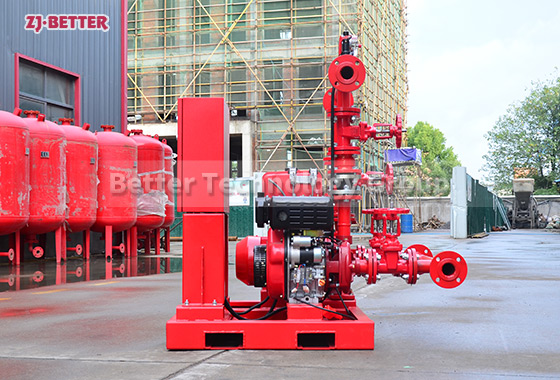

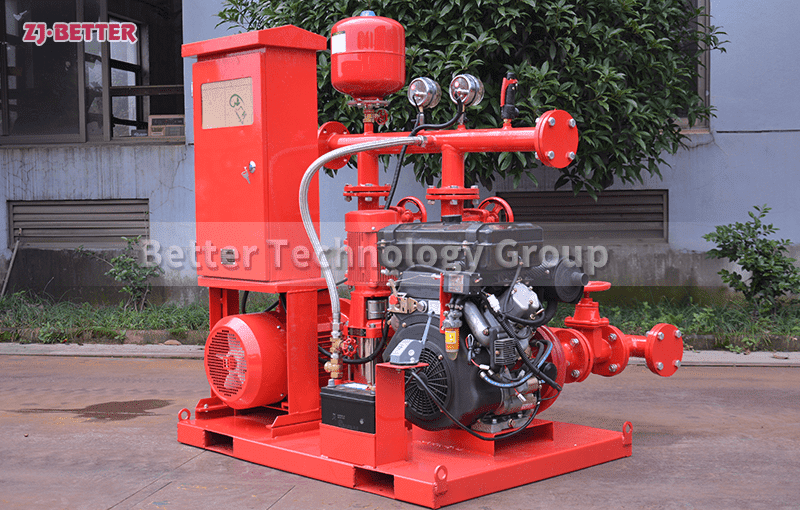

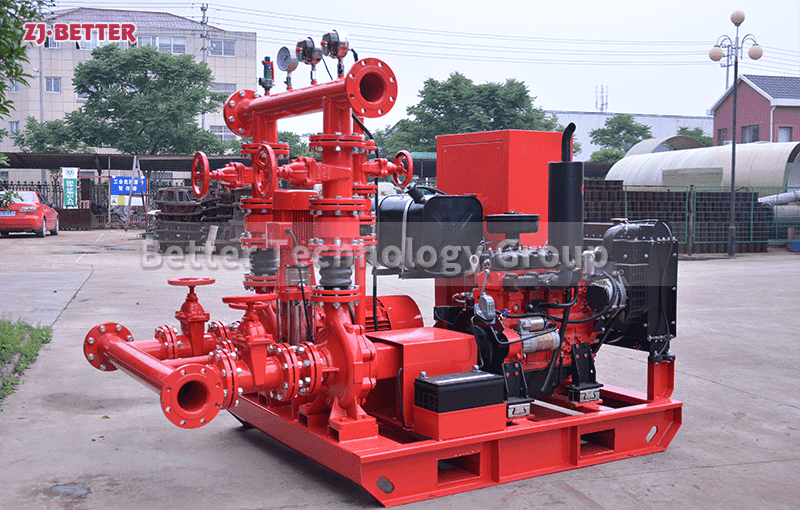

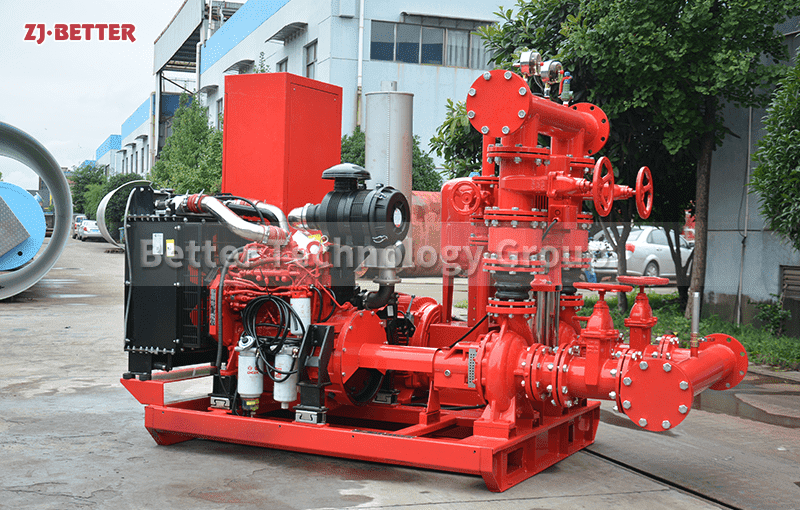

In the daily maintenance of the fire pump, we need to meet the following requirements: we need to ensure that the water inlet and outlet pipes, the various components of the controller, and the diesel engine system can work normally, and ensure that the power part is firmly connected to the water pump. We also need to check the opening status of the pump room, fire pump system, and various valves to ensure that the pump room has good heat dissipation conditions and that the components of the pump are in normal working condition.

Contact US

Get Price

Share:

Next:

Fire Pump Selection

Content

After understanding the requirements and content, it is the method, as follows:

Fire pump The fire pump should run at least once a week. The running time should be no less than 10 minutes for electric pumps and no less than 30 minutes for diesel pumps. Check whether the outlet pressure of the pumps meets the requirements.

Before the fire pump runs every week, check whether the pump set is in good condition. Requirements: ①The suction, release and bypass pipes of the pump can all be opened; ②The pump unit has no leakage; ③The pressure gauges of the inlet and outlet pipes are normal; ④The fire pool is full of fire water.

Before the fire water pump runs every week, check whether the electrical control part is in good condition. Requirements: ①The positive indicator light of the power switch is normal; ②The switching and conversion indicator lights are normal; ③The standby power is turned on, and the isolation switch is turned off; ④The alarm feedback signal indicator light is off, and the normal indicator light is on.

Before the fire pump runs every week, check that the switching between the main and standby power sources is normal, and check the backup power supply to see if the pump can be put into normal operation within 30 seconds; check whether the backup water pump can be automatically switched and put into operation.

Inquiry

More Fire Pump Set