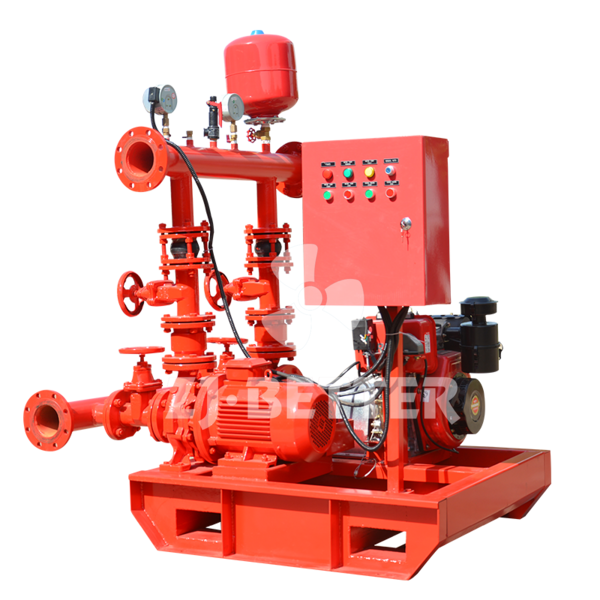

Fire pump set (diesel engine pump + jockey pump)

DJ Fire pump set Fire pump set consists of one pump coupled to diesel engine, jockey pump, pressure vessel, controller for manual or automatic operation of system and standard accessories mounted on base frame.And this fire pump system can be customized for different purposes such as high rise buildings, facilities,hospitals, supermarkets,shopping malls,villas,apartments,etc.

Automatic diesel pump unit: diesel water pump, jockey pump, steel structure base, battery, connecting wires, gate valve,check valve, flexible joints, automatic control panel.

When pressure drops below the set value, jockey starts running with the signal from the pressure switch and continues running for 10 minutes till the system pressure reaches the set value.

Fire Pump Control Panel is the Pump System brain that designed to Control & Monitor the operation of the Diesel, and Jockey Pumps drivers, and makes up pumps for both Manual & Automatic modes, as well as turns pumps drivers ON/OFF under specific conditions. Fire Pumps Series Controllers are pre-wired, tested before delivery and made ready for immediate usage.