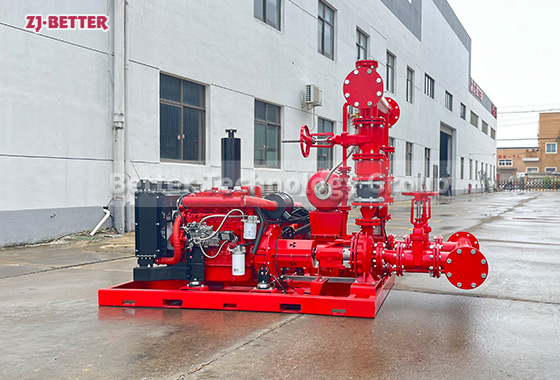

Fire Pump Set Test Site

This is a set of 250gpm @ 8bar fire pump sets. We manufacture in strict accordance with customer requirements. All products will be tested before leaving the factory to ensure that there are no problems. The design meets the national standard of general packaging, meets customer needs, and standard handling and transportation.

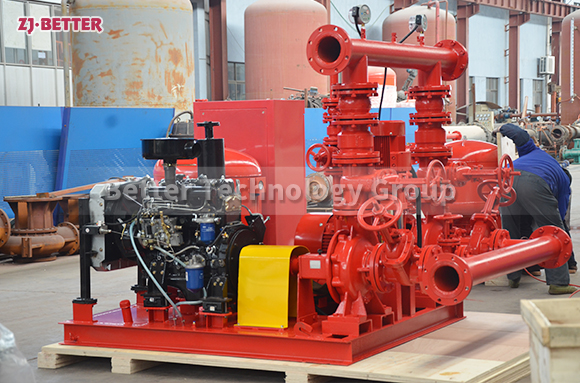

1. Electric pump, can use multistage pump, material can be cast iron, stainless steel, and bronze impeller

2. Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric and diesel engine pump

Jockey material casing: cast iron ,shaft and impeller SS304

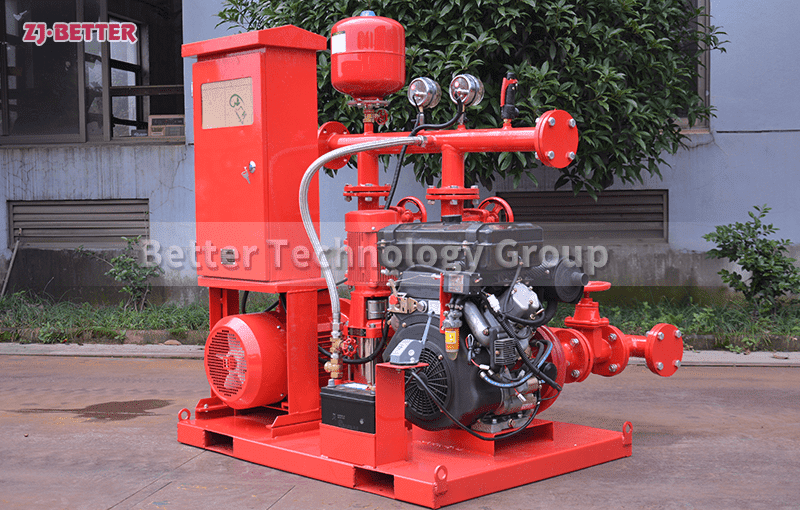

3. Control panel: Auto Control of electric pump and Jockey Pump with overload, over current protection.

The control system has current, voltage, power display, and the operating status display of fire pump and steady pressure pump, oil pressure, speed, running time display, manual pump control and automatic remote control

4. Accessories: check valve, gate valve, pressure vessel, generally 0.6mpa, 1.0mpa, 1.6mpa, Pressure Gauge, Pressure Sensor, Common Pipe for Suction and Discharge, Flexible Joints and Flanges, Common Base plant