Fire pump sets are suitable for any occasion

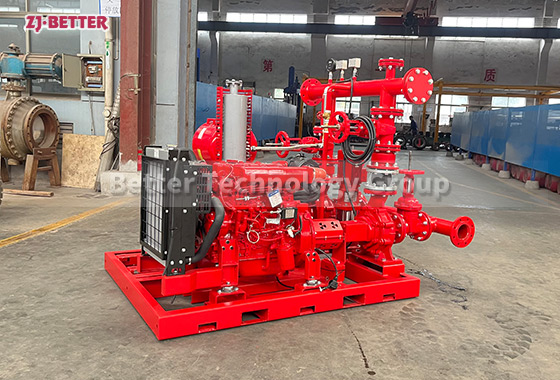

The dual power fire pump is composed of a fire water pump, a double shaft extension motor and a diesel engine. One end of the output shaft of the double shaft extension motor is connected with the input shaft of the fire pump, and the other end of the output shaft of the double shaft extension motor is One end of a clutch is connected, and the other end of the clutch is connected with the output shaft of the diesel engine. The fire water pump, the double-shaft extension motor, the clutch and the diesel engine are all fixed on the base. The double shaft extension motor, the clutch and the diesel engine are respectively electrically connected with a control circuit through an action driving circuit. With dual-power fire pumps, there is no need to configure a second fire pump, which reduces floor space and saves manufacturing costs.

Diesel engine fire pump has simple structure, reliable performance, small size, light weight, good corrosion resistance, low power consumption, convenient use and maintenance, suitable for urban environmental protection, construction, fire protection, chemical industry, pharmaceuticals, dyes, printing and dyeing, brewing, electricity, electroplating , papermaking, petroleum, mining, equipment cooling, tanker unloading, etc. Diesel engine fire pumps are used in warehouses, wharves, airports, petrochemicals, power plants, liquefied gas, textiles, ships, tankers, enterprise backup and other occasions for fire water supply, and can also be used for domestic water supply.