Fire pump sets are suitable for any occasion

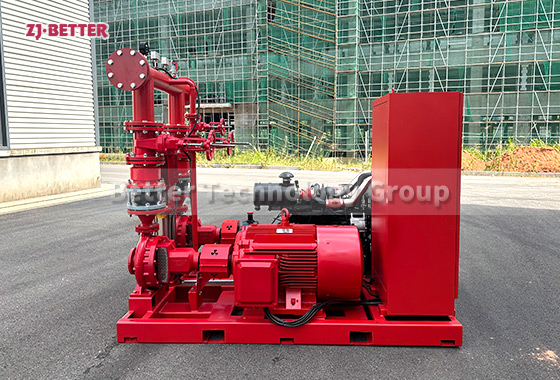

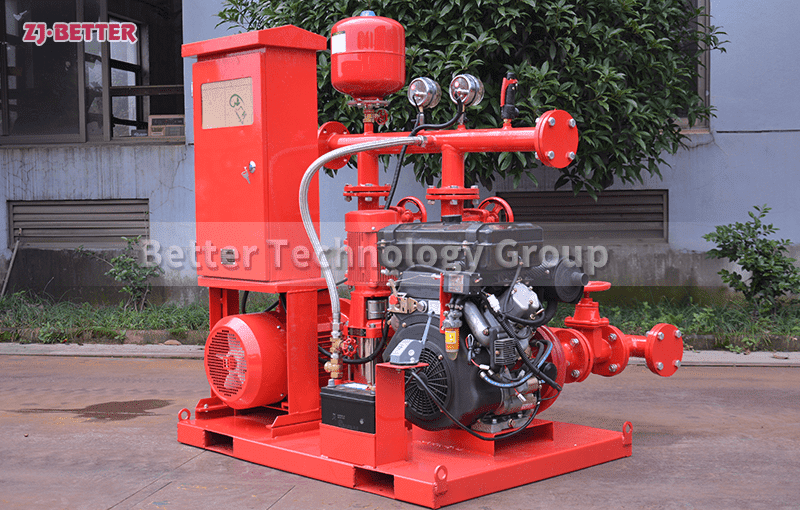

The fire pump unit is composed of a fire water pump, a double shaft extension motor and a diesel engine. One end of the output shaft of the double shaft extension motor is connected to the input shaft of the fire water pump, and the other end of the output shaft of the double shaft extension motor is connected to a One end of the clutch is connected, the other end of the clutch is connected with the output shaft of the diesel engine, and the fire water pump, the double-shaft extension motor, the clutch and the diesel engine are all fixed on the base. The double-shaft extension motor, the clutch and the diesel engine are respectively electrically connected with a control circuit through an action drive circuit. With dual-power fire pumps, there is no need to configure a second fire pump, which reduces floor space and saves manufacturing costs.

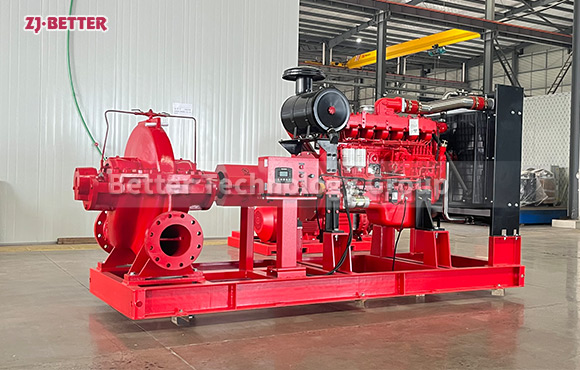

The advantage of the diesel engine fire pump set is that when a fire occurs, the power supply fails, and the electric fire pump set cannot be put into use normally, the diesel engine fire pump set can be put into operation automatically to ensure the normal fire fighting. Compared with the electric fire pump unit, it does not need long-term investment in power supply, saving the mains power supply transformer and normal expenses. Diesel engine fire pumps are equipped with various automatic functions to meet customer requirements, ensure long-term normal standby status of the equipment, and put it into fire fighting work at any time.