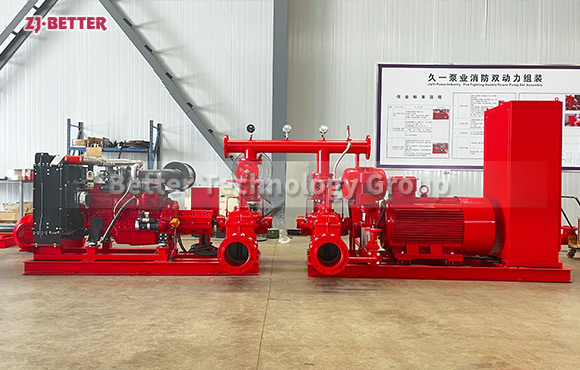

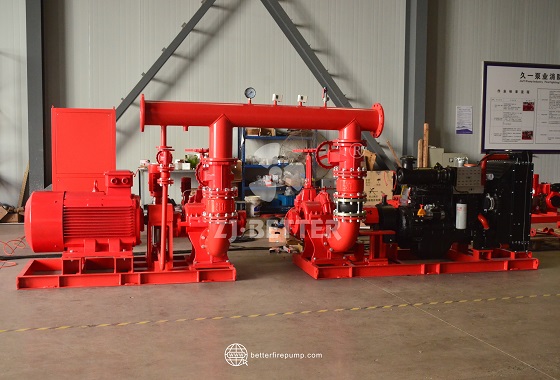

Fire Pump Sets From Chinese Manufacturers

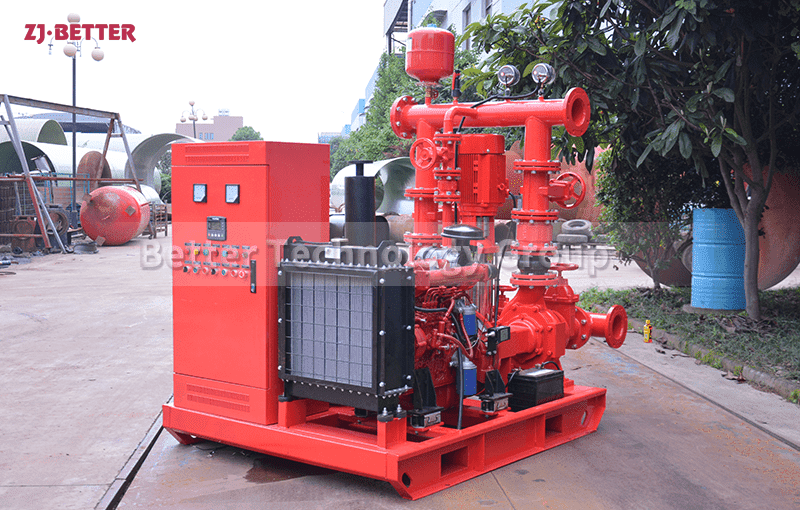

Diesel engine fire pump, as a fixed fire extinguishing equipment, has been widely used in fire diversion, especially in emergencies such as no power supply or abnormal power supply, other diesel engines can also be equipped as power engines according to the needs of users.

1. The anti-pump function is very powerful. We can set the control time during use, such as: preheating, pre-lubricating or timing start. The use of high-tech makes some complicated and time-consuming things easier in the past. The pre-heating setting greatly reduces the preparation time for rescue, allowing firefighters to rescue the first time. In the face of disasters, time is money and time. is life.

2. The head and flow can be controlled by adjusting the speed of the engine, and the height and size of the water flow become easier to control. When the nozzle is in a stable state, we can accurately spray the water source at the fire point by controlling the engine to extinguish the fire, which also reduces the difficulty of rescue for firefighters.

管道泵(不锈钢304316L).jpg)

.jpg)