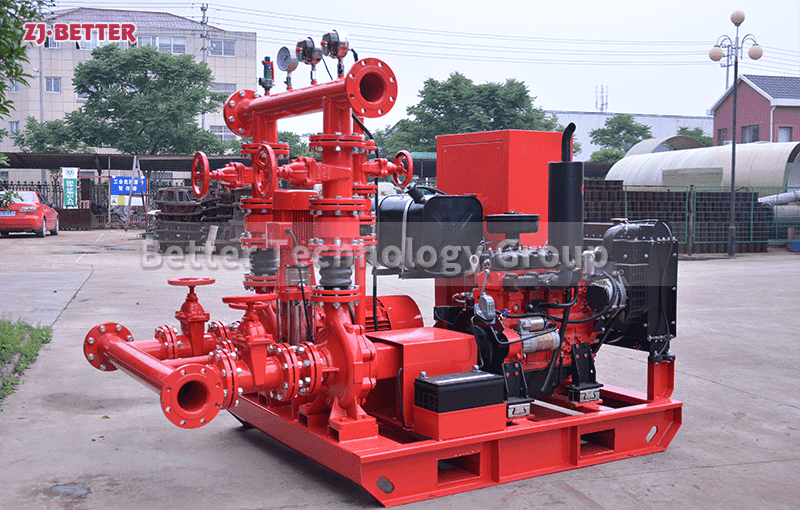

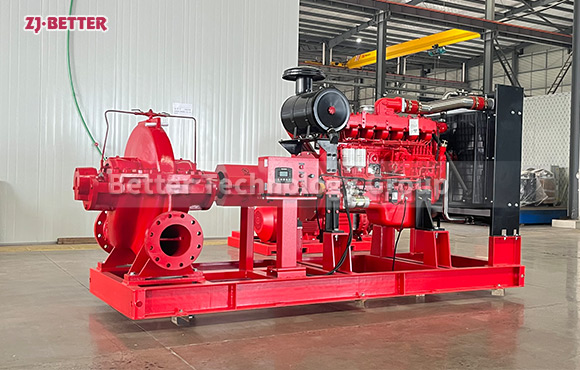

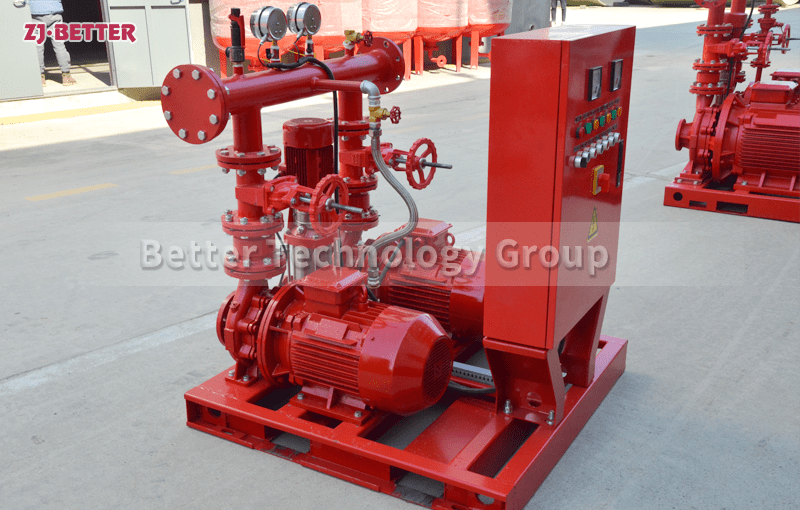

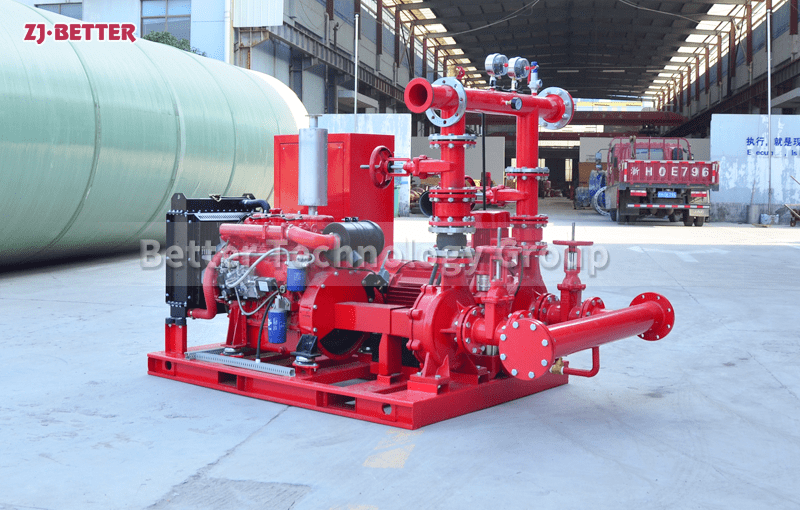

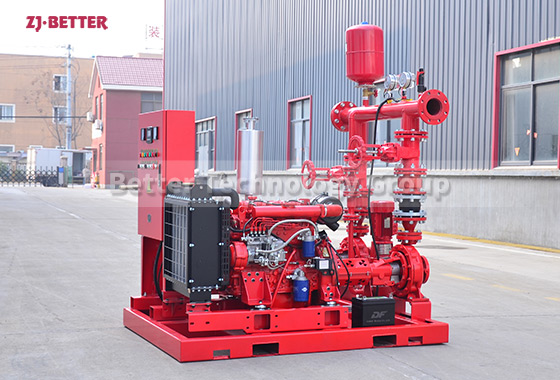

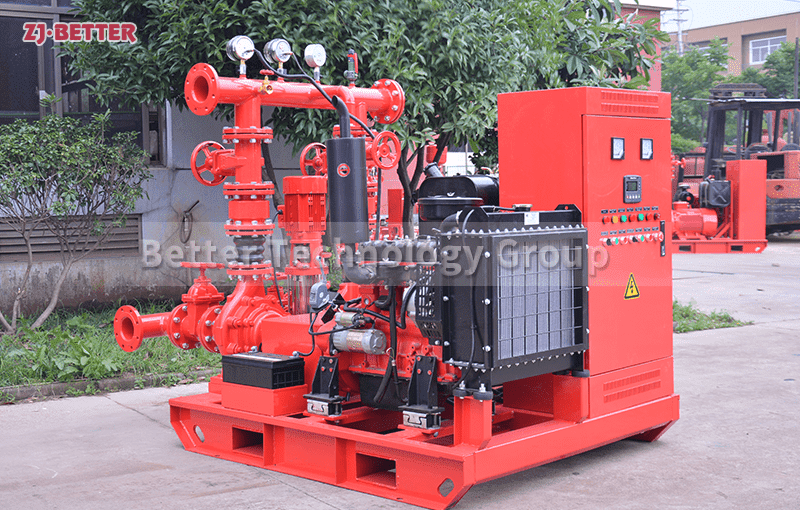

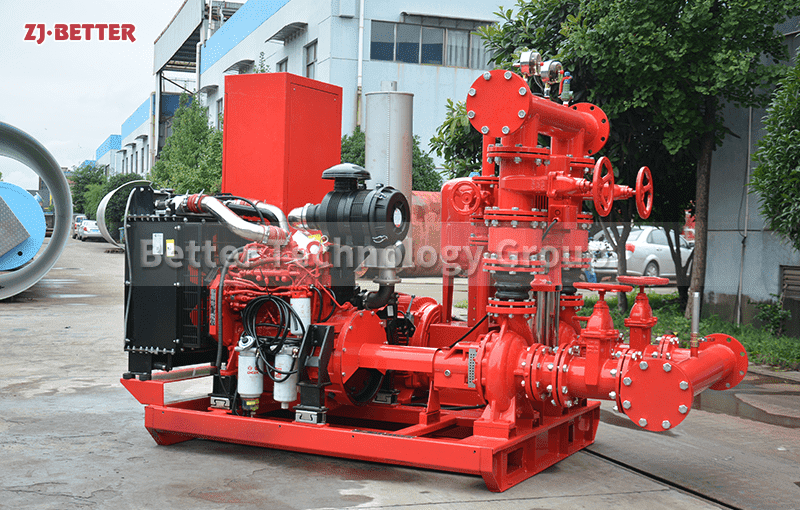

Fire Pump Sets Made To Order

The pump casing of the electric pump of the fire pump set can be made of cast iron or stainless steel, the impeller can be made of copper impeller, the flow head, pressure or other parameters of the diesel pump are the same as those of the electric pump, and the diesel engine is connected to the pump head through a coupling. The jockey pump is a vertical pump, and its technical parameters are different from those of electric or diesel pumps. Generally, the lift is higher than that of electric and diesel pumps, and can be customized.

Advantages of EDJ Fire Pumps:

–Switch Automatcally among the three pumps

–Both Manual and Automatic operation is available

–Can work when the power is off

–Easy installation 、Customized size and pump group

–YE3 high efficient motor with protection IP55 class F

–High performance and low power consumption

–Pump case with Anti-corrosive coating

–With quality NSK bearings, wear resistance mechanical seal

–Circult available up on request

–Different Mounting Styles

–Low Maintenance Cost and available spare parts