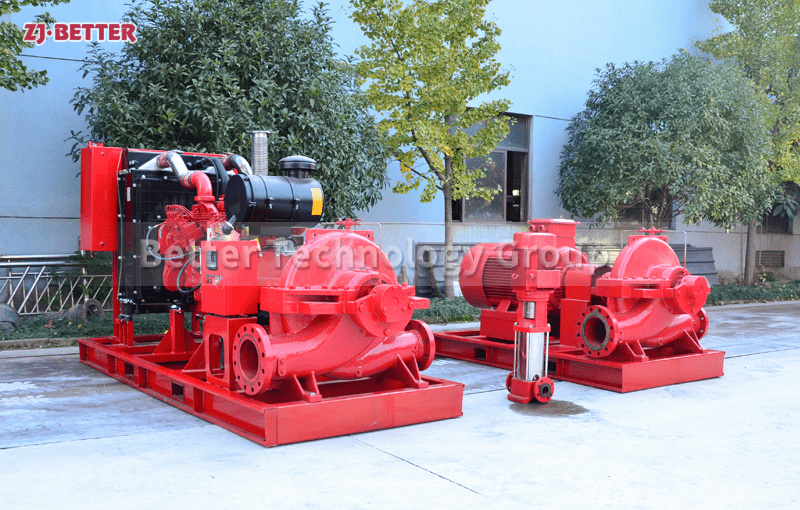

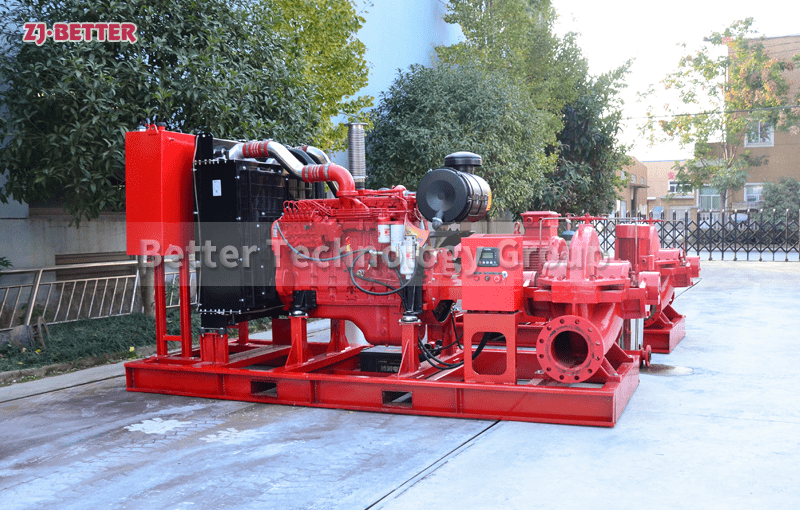

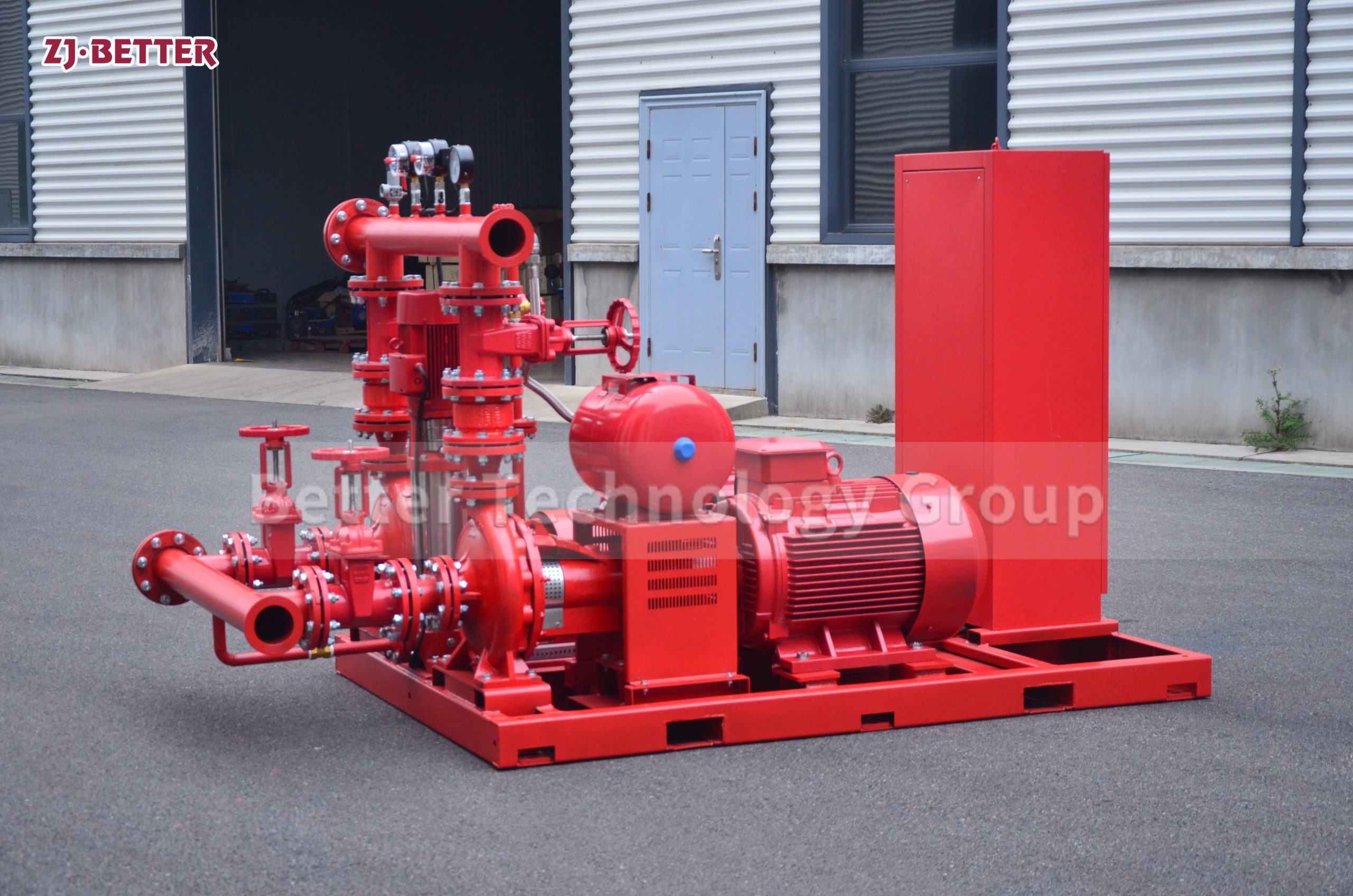

Fire pumps are mainly used for fire water

Fire pumps are mainly used for pressurized water delivery in firefighting system pipelines, and can also be used in industrial and urban water supply and drainage, high-rise building depressurized water delivery, long-distance water delivery, heating, bathroom, boiler cold and warm water circulation pressurized air conditioning refrigeration system water delivery and equipment matching, etc.

The fire pump is mainly used to pressurize and send water to the fire system pipeline. It can also be applied to industrial and urban water supply and drainage, high-rise building pressure water supply, long-distance water supply, heating, bathroom, boiler cold and warm water circulation pressurized air-conditioning refrigeration system water supply and equipment matching and other occasions. The fire pump has the advantages of simple structure, stable performance, high speed, small size, light weight, high efficiency, large flow, easy operation and maintenance, etc.