Fire pumps are used in fire water systems

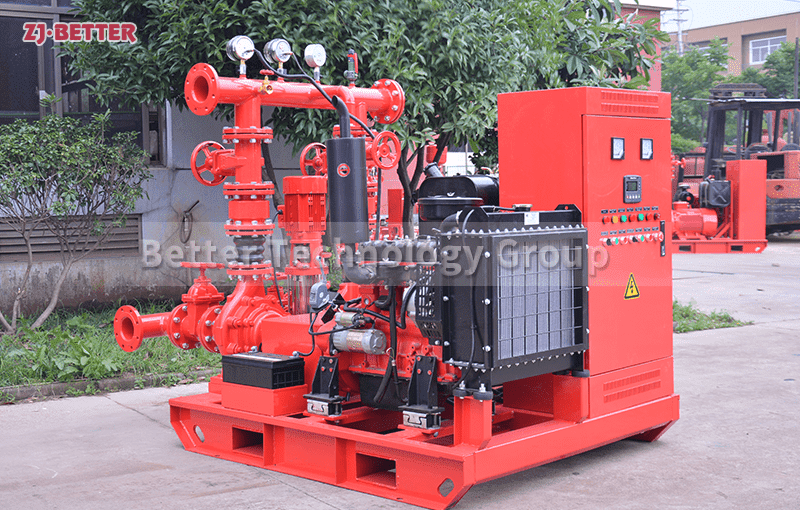

The fire pump is naturally used in the fire water system, and the technology and raw materials used are all required on site. There are many types of fire pumps and different performances. There may be overlapping performance ranges or large differences in performance. We need to consider the specific functions of the site, such as electric motor fire pumps or diesel engine fire pumps, vertical long-axis fire pumps or horizontal split double pumps. Suction fire pump, horizontal single-stage fire pump, etc., we should choose according to actual needs.

The importance of the fire pump is to provide sufficient fire-fighting water to ensure that the required water is provided during emergency use. There are different types of fire-fighting water pumps, but they are widely used in fire-fighting and environmental protection due to their fully sealed, various types, and corrosion-resistant characteristics. , water treatment and other fields, realize the transportation of various liquids, and is an ideal pump for fire fighting. There are vertical and horizontal installation forms, and the type is determined according to the actual situation of fire protection. When choosing a fire pump, on the premise of satisfying the water flow, working head and working form, several aspects such as the number of redundancy and installation and operating conditions should also be considered. The selection of fire pump is very important. Different environments are suitable for fire pumps with different performances. Electric motor fire pumps, diesel engine fire pumps, horizontal single-stage fire pumps and horizontal split double-suction fire pumps are all commonly used types, with different performance ranges. The same, the role in the fire water system is also different.