Fire Safety Assurance with EJ Fire Pump Sets

Flow: 14-2700 GPM

Head: 12-80 meter

Speed: 740-2900r/min

Material: HT200, SS304, Bronze

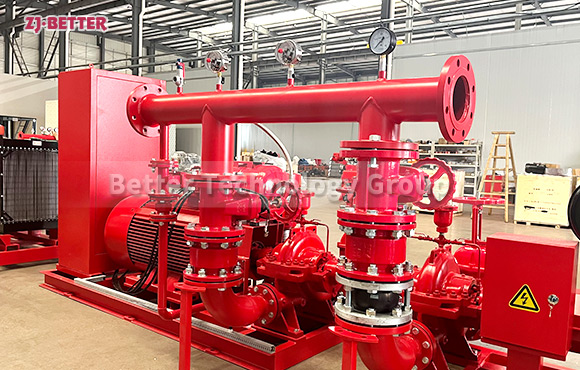

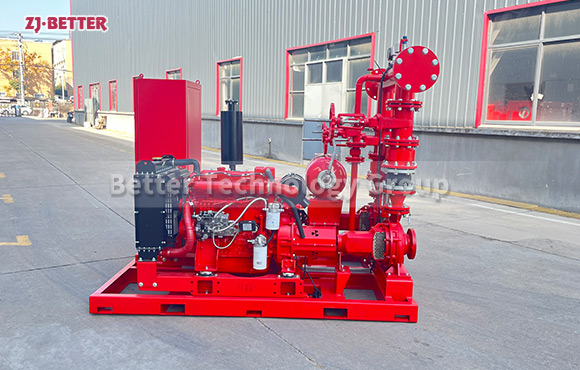

The EJ Dual Power Fire Pump System is an innovative and reliable fire protection solution. Combining an electric pump for robust water pressure and flow with a top-quality jockey pump for stable pressure maintenance, this system ensures efficient and timely water supply during fires. With advanced automation, remote monitoring, and energy-saving features, the EJ Dual Power Fire Pump System is a trusted choice for commercial, industrial, and residential applications.

Types of pumps used for fire service include: End Suction Pump, Split Case Pump, Vertical Inline Pump and Vertical Turbine Pump.

1.Electric motor driven pump, can use single stage pump, horizontal split case pump, end suction pump,multistage pump.

2.Diesel engine pump, with capacity and head equal to electric pump, with fuel tank, water tank, fan,control box.

3.Jockey pump, horizontal or vertical, capacity will be small, but head should be higher than electric anddiesel engine pump.

4.Control panel: Auto Control of electric pump, diesel engine pump and Jockey Pump with overload, overcurrent protection.

The EJ Dual Power Fire Pump System boasts several admirable features. It incorporates advanced automation technology, enabling real-time monitoring of the fire protection system’s operation. It also offers remote monitoring and control capabilities, allowing users to stay informed about the system’s performance. Additionally, it is highly efficient and energy-saving, reducing energy consumption and operational costs.

In summary, the EJ Dual Power Fire Pump System is a powerful, reliable, and highly intelligent fire pump system. Its introduction represents a significant advancement in fire protection systems, ensuring quick response and stable water supply in the event of a fire. Whether for commercial buildings, industrial facilities, or residential areas, the EJ Dual Power Fire Pump System is a trusted choice.