Flexibility and Convenience: Choosing drought-resistant emergency mobile pump for Various Emergency Situations

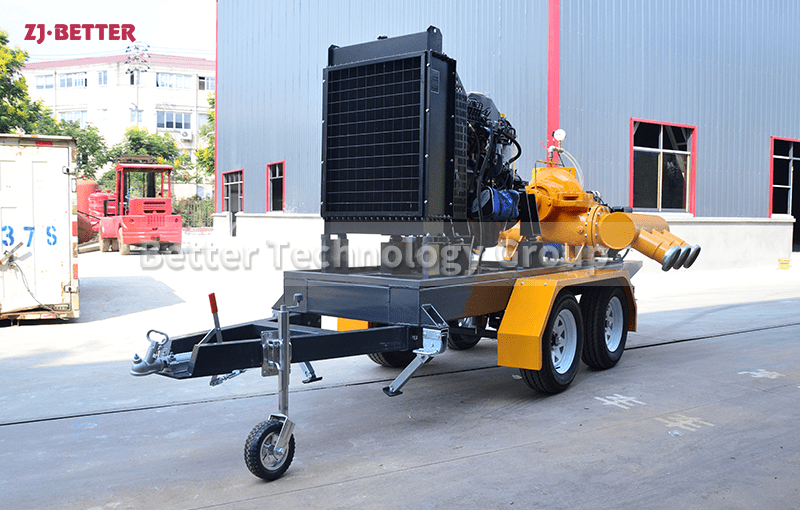

We take pride in introducing our emergency mobile pump solution designed to tackle flood control and drought scenarios: Flood control and drought-resistant emergency mobile pump. This pump station excels in self-priming capabilities (≤9m) and offers efficient flow control (300-3500m³/h), withstanding pressures ranging from 5 to 200BAR. It is suitable for diverse applications, including agricultural irrigation, industrial drainage, and more.

Our mobile pump station is manufactured using a variety of materials, including pig iron and stainless steel, ensuring durability and reliability. Whether it’s providing ample water supply for agricultural irrigation or handling wastewater in industrial drainage, our mobile pump station is up to the task.

Not only does this mobile pump station excel in flood control and drought emergencies, but it is also suitable for various temporary scenarios. It can be rapidly deployed, delivering reliable liquid handling capabilities when needed. Whether you are facing natural disasters, agricultural irrigation needs, or industrial drainage challenges, our mobile pump station will be your trusted partner.

Self-priming height: ≤9 m

Head(BAR): 5~200

Flow rate(m³/h): 300~3500

Materials: Pig iron, stainless steel

Main applicant:

1.There is no fixed pump station and no power supply area;

2.Assault flood control;

3. Drought and rescue;

4. Agricultural irrigation, aquaculture;

5. Various temporary pumping occasions;

6. Industrial and municipal drainage.