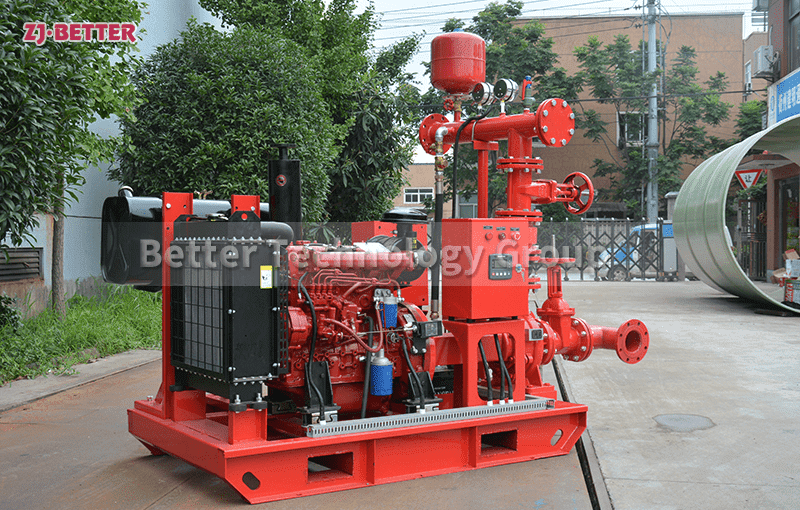

Flood control and drought relief emergency mobile hand-held diesel fire pump

The main advantage of the hand-held diesel fire pump is the high lift, which can reach 90 meters. It is generally used for fire emergency fire prevention, forest emergency fire prevention, and factory fire protection. When the diesel engine fire pump is working, the auxiliary impeller is together with the pump main shaft Rotating, the liquid in the auxiliary impeller will also rotate together, and the rotating liquid will generate an outward centrifugal force. On the one hand, this centrifugal force resists the liquid flowing to the mechanical seal, reducing the pressure at the mechanical seal. On the other hand, it prevents the solid particles in the medium from entering the friction pair of the diesel engine fire pump seal, reduces the wear of the mechanical seal grinding block, and prolongs its life. The auxiliary impeller of the diesel engine fire pump can not only play a sealing role, but also reduce the axial force. In the diesel engine fire pump, the axial force is mainly caused by the pressure difference force of the liquid acting on the impeller and the gravity of the entire rotating part. The direction of action of these two forces is the same, and the resultant force is formed by the addition of the two forces.

The correct maintenance of diesel engine fire pumps, especially preventive maintenance, is easy and economical maintenance, so it is the key to prolong and reduce the cost of use. Daily maintenance can be carried out according to the following steps to check the amount of fuel in the fuel tank, observe the amount of fuel stored in the fuel tank, and refill as needed. Check the oil level in the oil pan, and observe whether the oil level reaches the mark on the oil dipstick. If it is insufficient, add to the specified amount, but not exceed the upper limit of the scale mark.