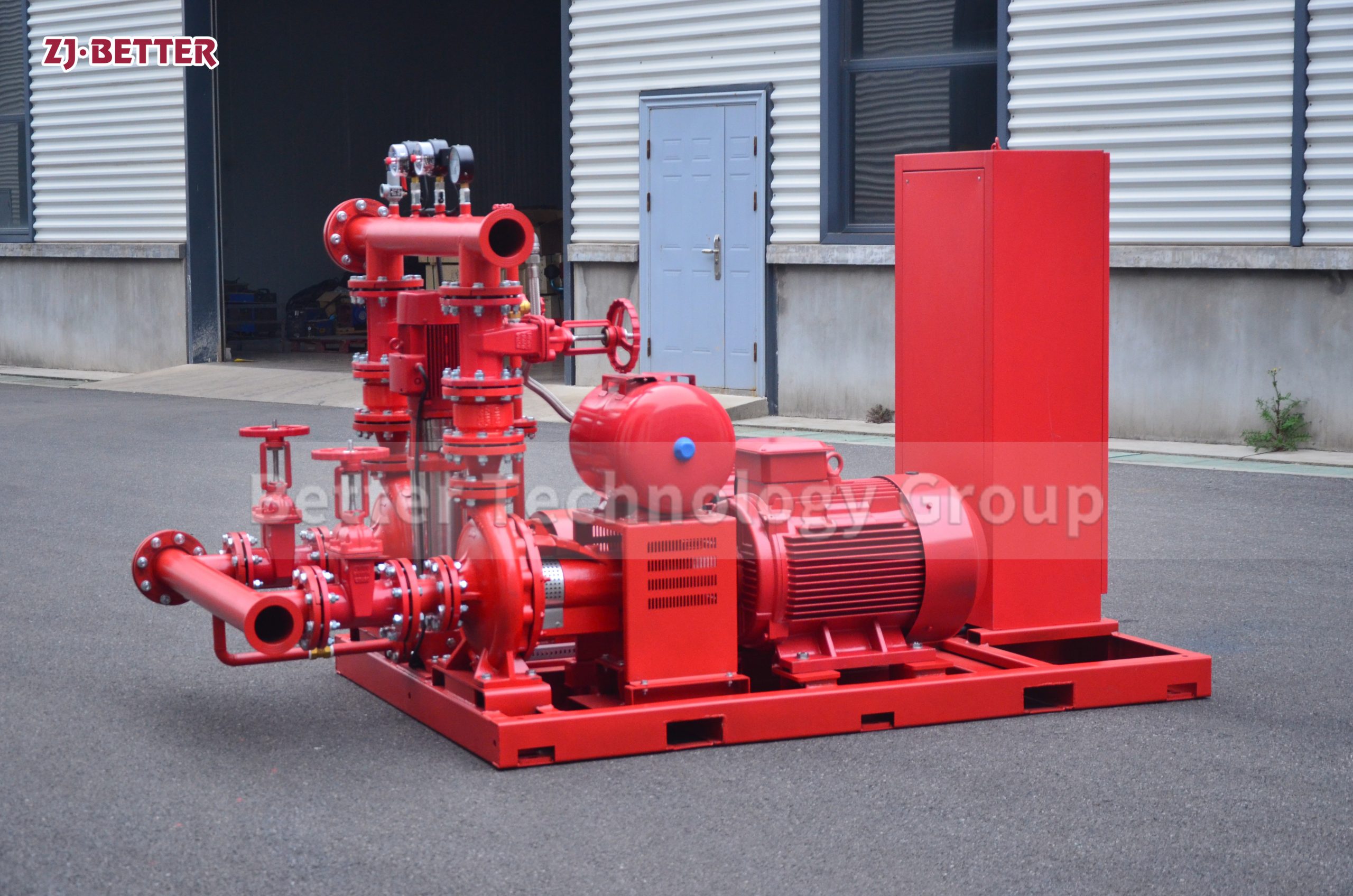

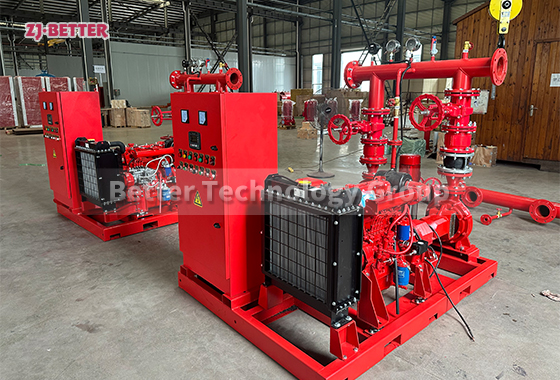

Function introduction of diesel engine fire pump set

Diesel engine fire pump is a kind of mechanical and electrical integration equipment that is directly driven by diesel engine fire pump and can start and complete water supply in a short period of time. The diesel engine pump set is driven by diesel and does not need an external power supply. Diesel engine water pumps are suitable for various fire water supply occasions such as agricultural irrigation, emergency rescue, smelting, hangars, petrochemical oil depots, power plants, liquefied gas stations, textiles, etc., especially where there is no electricity, When the power grid is not satisfactory, it is most suitable to choose a diesel engine to drive the water pump.

1. The diesel engine pump set is easy to use. It can be equipped with remote transmission instruments and meters, which can be connected to the control center as needed. It is easy to install and use, and easy to maintain.

2. The diesel engine pump set has a high degree of automation, with automatic, manual and fault self-inspection functions, the whole process monitors the working status, can recover faults and automatically restart the function of failure to start, automatic pre-lubrication and pre-heating, making the equipment start-up safer and more reliable .

3. The diesel engine pump set has the functions of remote control and remote transmission control in the central control room, and also has field bus connection.