Functional characteristics of domestic water supply equipment

When a partial failure of the equipment occurs, the emergency function can be enabled to continue the water supply. The equipment can be automatically connected to the municipal water supply network, and has dual constant pressure functions, which can meet the normal pressure and flow of domestic and production water, and can automatically switch to high-pressure and large-flow water supply when a fire occurs, and can be used for multiple purposes.

1. No noise: The living air pressure water supply equipment adopts modern design concept, fully considers the requirements of modern people on the environment, selects a special frequency converter for silence, and uses the noise reduction design method, so the life air pressure water supply equipment system can run ultra-quietly.

2. Power failure and continuous water supply: When the power supply line fails, the system can realize power failure and continuous water supply, that is, the system automatically switches to municipal tap water pressure water supply during power failure.

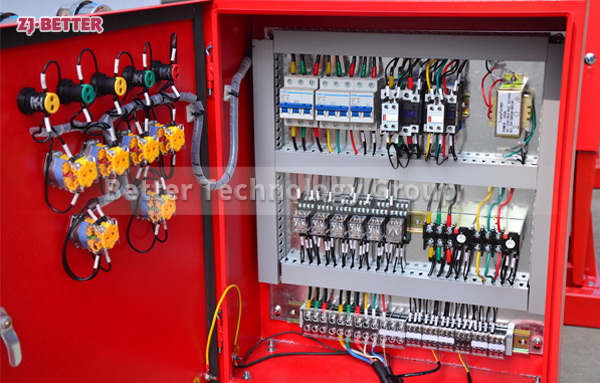

3. High degree of automation: The life air pressure water supply equipment can realize fully automatic control, with manual/automatic switching, timing rotation of main and auxiliary pumps, pressure adjustment, constant pressure, high and low voltage protection, phase loss protection, leakage protection, overload protection, overheat protection, Water shortage protection, water leakage detection and compensation, stop without water, instantaneous trip protection and other functions, and the man-machine interface can be configured according to user needs, visual remote adjustment, monitoring and maintenance.