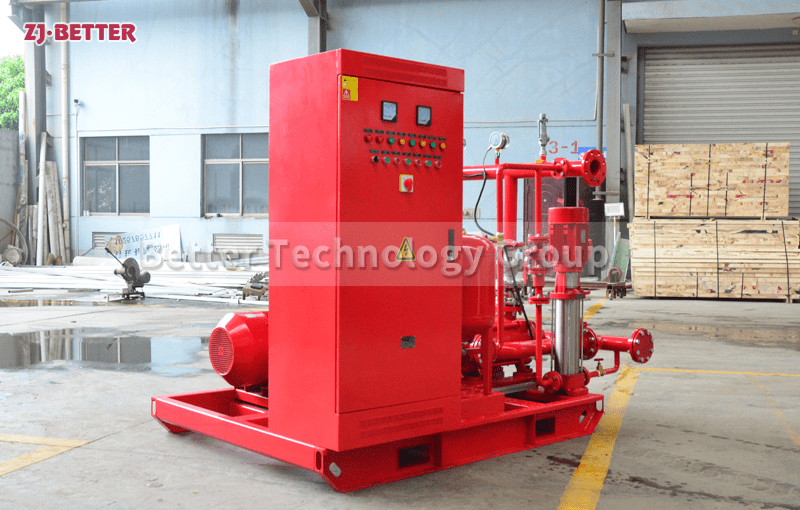

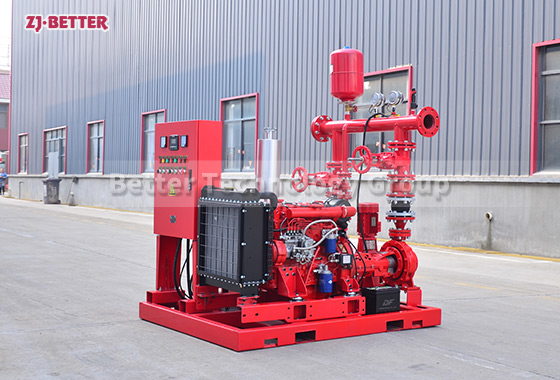

High-Quality EDJ-ISW Fire Pump

EDJ-ISW fire pump is composed of electric pump + diesel engine pump + jockey pump. It is suitable for fire water, but also for industrial city water supply and drainage, high-rise building pressurized water supply, long-distance water supply, heating, bathroom, boiler cold and warm water circulation pressurization Air-conditioning refrigeration system water supply and equipment matching and other occasions.

The ISW horizontal electric fire pump is composed of two parts, the motor and the pump. The pump and the motor are coaxial, which simplifies the connection of the pipeline. The pump inlet and outlet are on the same horizontal axis, and the diameter and specifications are the same. . The pump is provided with a mounting base, which is easy to install and increases the stability of the pump operation. The pump seal adopts mechanical seal, which has the characteristics of reliable sealing and no leakage. The axial force of the pump is balanced by the impeller with a balance ring. The inlet and outlet flanges of the pump are designed according to the pressure of 1.6MPa, and the pipeline is convenient to match. The pump rotor has small winding, stable operation, low vibration, low noise and long service life.