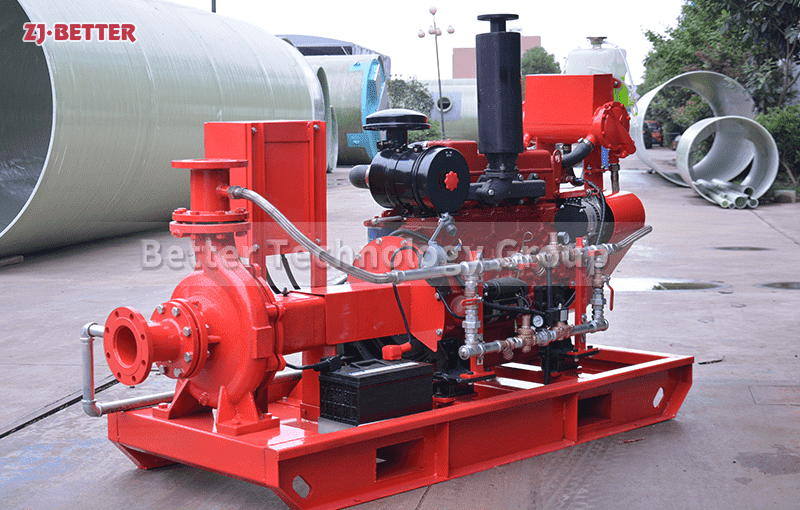

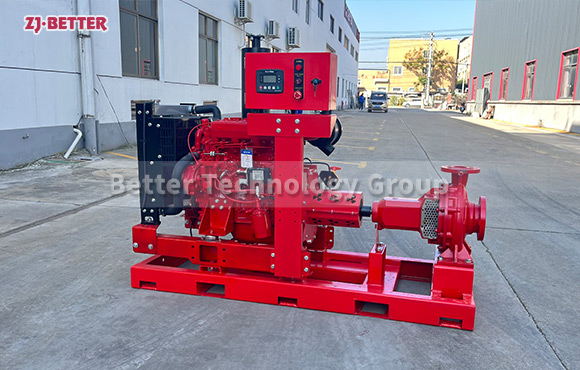

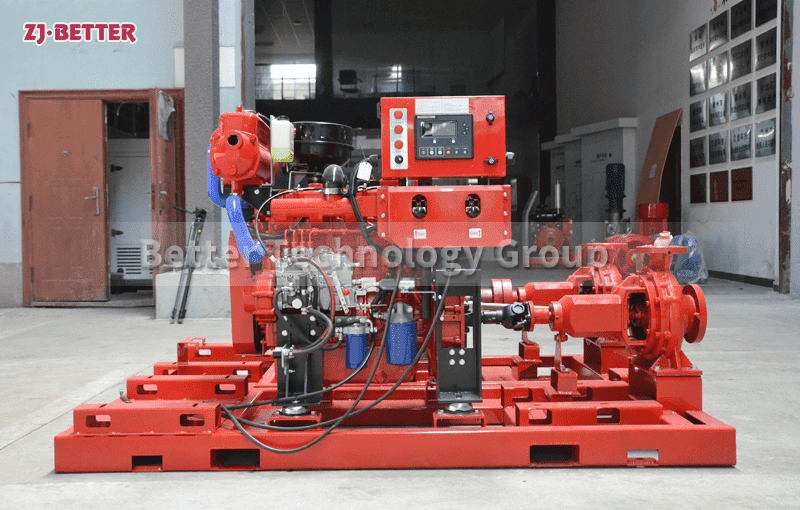

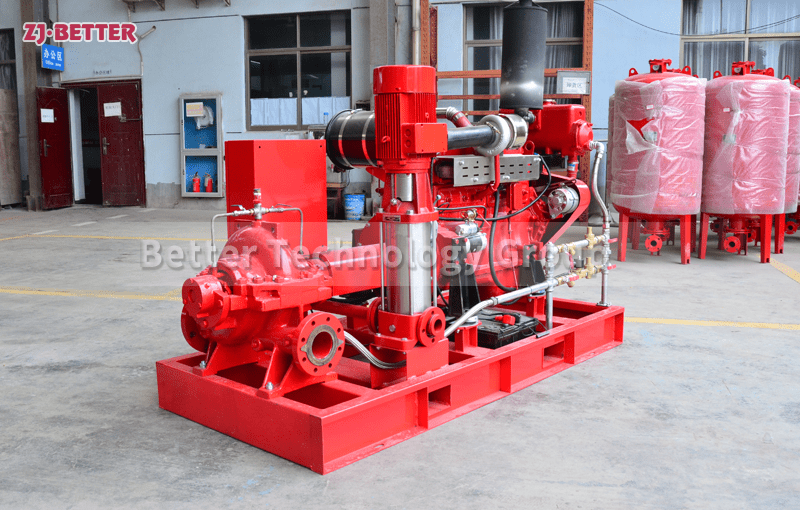

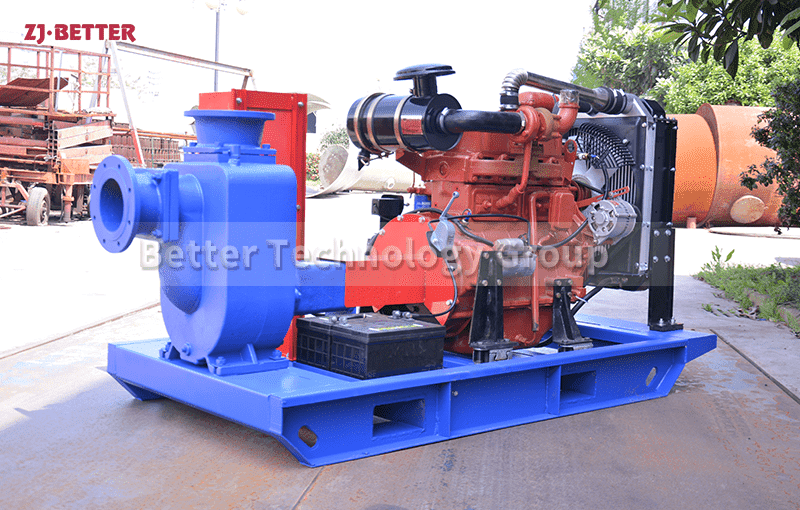

Horizontal end suction diesel engine pump

XA Horizontal end suction Diesel fire pump has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long life, easy installation and maintenance.

XA series single-stage centrifugal pump is the earliest single-stage single-suction centrifugal pump product launched by Better (China) Technology Co., Ltd. This product combines the advantages of similar products in China and abroad, and is designed with excellent hydraulic model. Therefore, its excellent hydraulic performance and structural characteristics ensure that users can effectively reduce the operation cost of pumps in various applications.

XA Horizontal end suction Diesel fire pump has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long life, easy installation and maintenance.

XA series single-stage centrifugal pump is the earliest single-stage single-suction centrifugal pump product launched by Better (China) Technology Co., Ltd. This product combines the advantages of similar products in China and abroad, and is designed with excellent hydraulic model. Therefore, its excellent hydraulic performance and structural characteristics ensure that users can effectively reduce the operation cost of pumps in various applications.