How do fire pumps contribute to fire safety in public transportation systems, such as subway stations and railways?

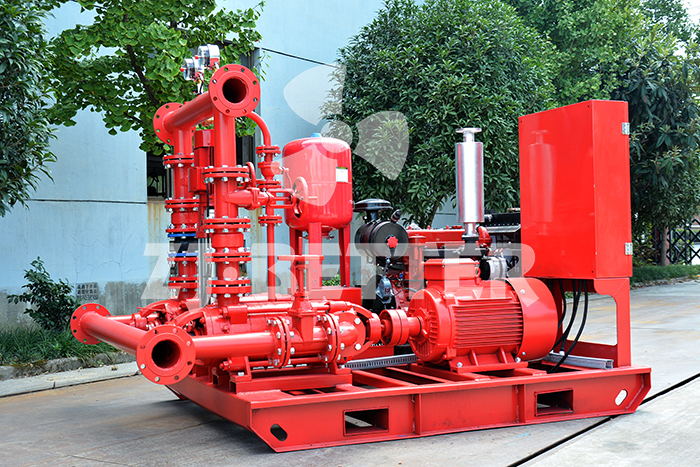

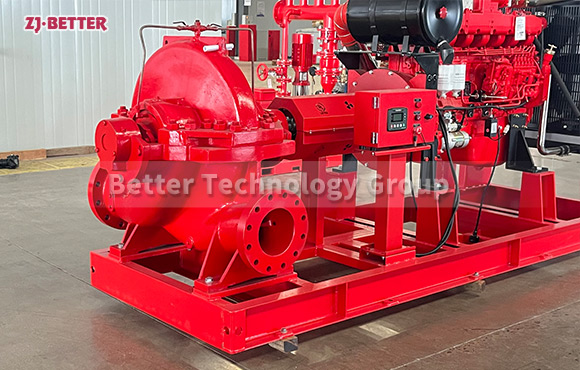

Public transportation systems, including subway stations and railway terminals, are complex environments with high volumes of passengers and potential fire hazards from electrical equipment, flammable materials, and mechanical systems. Fire pumps are vital in these settings for delivering the water or suppression agents necessary to extinguish fires in tunnels, platforms, and adjacent facilities. Jockey pumps ensure constant pressure in the system, so fire suppression mechanisms like sprinklers, hydrants, and standpipes are always prepared to respond. Given the confined and underground nature of many transportation hubs, fire protection systems must be capable of addressing fires in tight, poorly ventilated spaces while facilitating the safe evacuation of passengers. The pumps also need to support fire hose connections for firefighters, who might need to cover long distances within tunnels or elevated railways. Regular inspections and emergency drills are essential to ensure that fire pumps are fully operational and integrated with ventilation and evacuation systems, providing a coordinated response to fire emergencies in these high-risk, densely populated environments.

Public transportation systems, including subway stations and railway terminals, are complex environments with high volumes of passengers and potential fire hazards from electrical equipment, flammable materials, and mechanical systems. Fire pumps are vital in these settings for delivering the water or suppression agents necessary to extinguish fires in tunnels, platforms, and adjacent facilities. Jockey pumps ensure constant pressure in the system, so fire suppression mechanisms like sprinklers, hydrants, and standpipes are always prepared to respond. Given the confined and underground nature of many transportation hubs, fire protection systems must be capable of addressing fires in tight, poorly ventilated spaces while facilitating the safe evacuation of passengers. The pumps also need to support fire hose connections for firefighters, who might need to cover long distances within tunnels or elevated railways. Regular inspections and emergency drills are essential to ensure that fire pumps are fully operational and integrated with ventilation and evacuation systems, providing a coordinated response to fire emergencies in these high-risk, densely populated environments.