How does the mobile pump unit work?

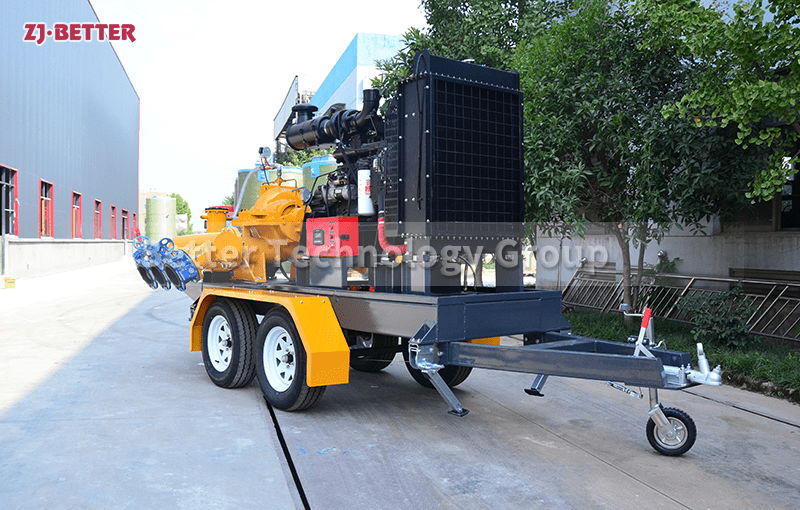

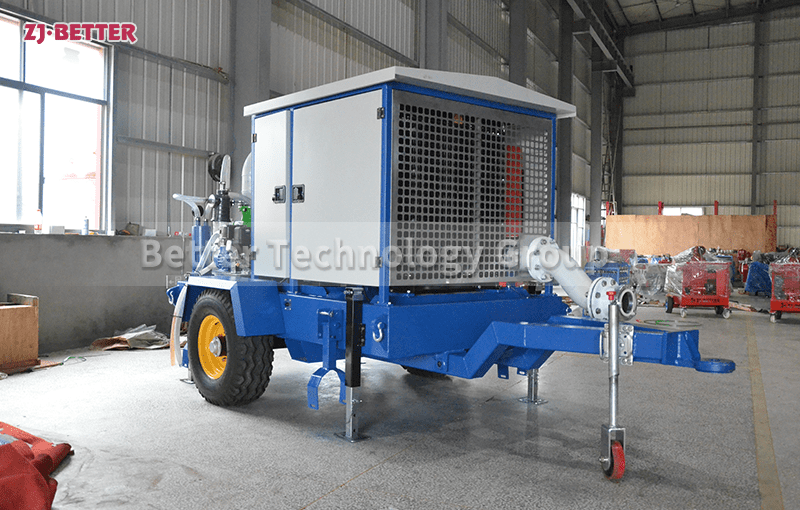

A mobile pump unit is a versatile device designed to transfer fluids, such as water, from one location to another. Its operation can vary based on the specific type of pump used and its intended application. Here’s a general overview of how a centrifugal mobile pump unit works:

1. Suction: The process begins by positioning the pump unit near the water source or the fluid to be pumped. The unit typically has a suction inlet with a strainer or filter to prevent large debris from entering the pump. When the pump is started, the suction process begins.

2. Priming: Centrifugal pumps often require priming, which is the process of filling the pump casing and the suction line with fluid to create an initial vacuum that enables the pump to pull in more fluid. Some mobile pump units are equipped with self-priming capabilities, while others might need manual priming.

3. Impeller Action: The pump unit is powered by a diesel engine or another power source. The engine drives the impeller, which is a rotating component with curved blades. As the impeller rotates, it creates a centrifugal force that pushes the fluid away from the center of rotation.

4. Centrifugal Force: The centrifugal force generated by the impeller causes the fluid to move radially outward within the pump casing. This action creates a low-pressure region at the center of the impeller, which draws more fluid from the suction line into the pump.

5. Discharge: As the fluid moves outward and gains energy from the impeller’s rotation, it enters the pump’s discharge chamber. The discharge chamber typically has a larger diameter than the suction inlet, allowing the fluid to slow down and convert its kinetic energy into pressure energy.

6. Pressure Increase: The kinetic energy of the fluid is transformed into pressure energy as it slows down within the discharge chamber. This pressure energy is what allows the pump to overcome the resistance in the discharge line and push the fluid to its intended destination, such as irrigation pipes, fire hoses, or storage tanks.

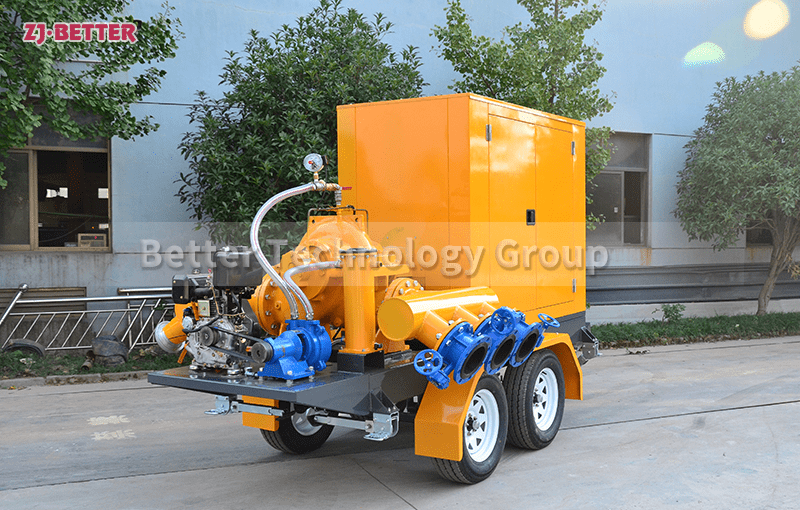

7. Outlet: The pump unit has a discharge outlet, usually connected to hoses, pipes, or other delivery mechanisms. The fluid exits the pump through the outlet and is directed to where it’s needed, such as a field, fire scene, or another location.

8. Control and Monitoring: Modern mobile pump units often come equipped with various controls and monitoring features. These might include pressure gauges to monitor the pressure at the discharge, engine temperature sensors, and safety shutdown systems to protect the pump from overheating or low oil pressure.

In summary, a mobile pump unit operates by using the rotational energy of an impeller to create centrifugal force, which in turn moves and pressurizes the fluid. The pump unit’s mobility allows it to be positioned where it’s needed most, making it a valuable tool for various applications such as agriculture, firefighting, construction, and emergency response.

.jpg)