How does the multistage horizontal EDJ fire pump set work?

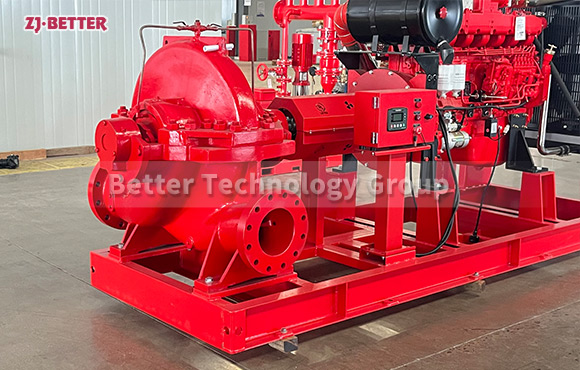

A multistage pump refers to a pump with two or more impellers, which can absorb and press water in stages and multiple stages, so as to lift the water to a high position, and the lift can be increased or decreased according to the needs of the pump impeller. The multistage pump can be equipped with a four-stage motor by increasing the number of impellers when the single-stage pump head needs to be equipped with a two-stage motor, which can improve the service life of the pump and reduce the noise of the unit. It is placed flat on the ground, with better stability, large flow and head, and wider application.

When the water inlet pipe of the multi-stage pump contacts the water source, the liquid is sucked from the water inlet section, pressurized by the first-stage impeller, and then transferred to each secondary impeller, and pressurized step by step to form the required pressure, which is generated by the high-speed rotation of the impeller. Under the action of the centrifugal force of the impeller, the water in the flow channel of the impeller is thrown around and pressed into the volute, the inlet of the impeller forms a vacuum, and the water in the pool is sucked along the suction pipe under the external atmospheric pressure to supplement this space. Then the inhaled water is thrown out by the impeller through the volute and enters the water outlet pipe. If the impeller of the centrifugal pump rotates continuously, water can be continuously absorbed and pressed, and the water can be continuously raised from low to high or far away. During operation, due to the pressure, a huge force (we call it axial force) is gradually formed to promote the forward movement of the impeller and other rotor components; in order to reduce the axial force, a balance system (balance ring embedded In the water outlet section, the balance disc is mounted on the main shaft and moves back and forth by the pressure of the water flow). During operation, the high-pressure water opens the balance disc and the balance ring to form a reaction force, thereby offsetting the axial force. water intake.