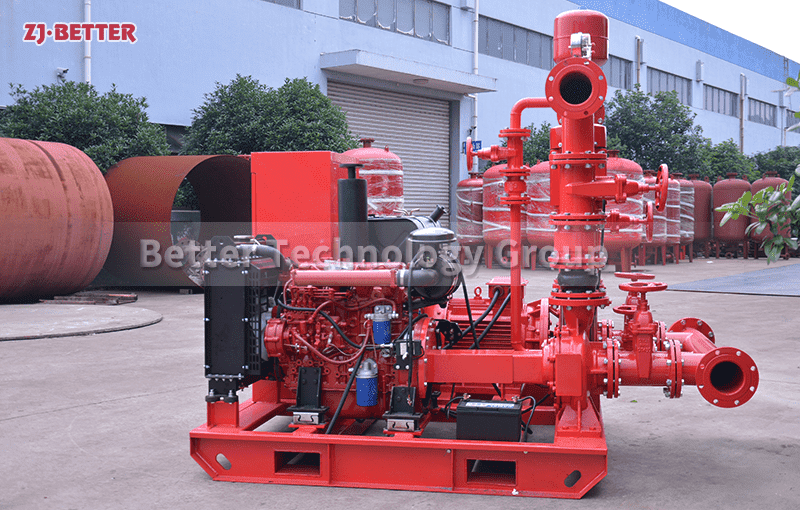

How should the pump casing of the fire pump be maintained?

The fire pump’s pump casing should be regularly inspected for signs of corrosion, warping, and damage. The casing should also be visually inspected for leakage, and all fittings should be tested regularly to ensure they are properly sealed. All gaskets and seals should be checked for wear and replaced when needed. The impeller should be routinely checked to make sure it is free of debris and that all blades are in good condition. Any abnormal sound or vibration should be investigated immediately.

The fire pump‘s pump casing should be regularly inspected for signs of corrosion, warping, and damage. The casing should also be visually inspected for leakage, and all fittings should be tested regularly to ensure they are properly sealed. All gaskets and seals should be checked for wear and replaced when needed. The impeller should be routinely checked to make sure it is free of debris and that all blades are in good condition. Any abnormal sound or vibration should be investigated immediately.