How to choose a high- quality diesel machine fire pump

First of all, when buying any outfit, the cheaper the better. What we should pay further attention to is the performance and quality of the product. frequently blindly pursue low prices, it’s delicate to guarantee product quality and colorful services( including after- deals service, form, conservation,etc.).

1. descry the material of diesel machine fire pump

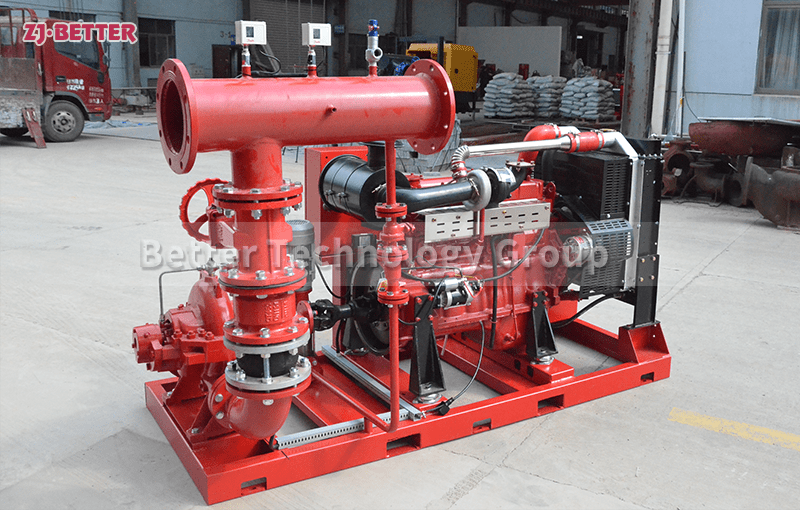

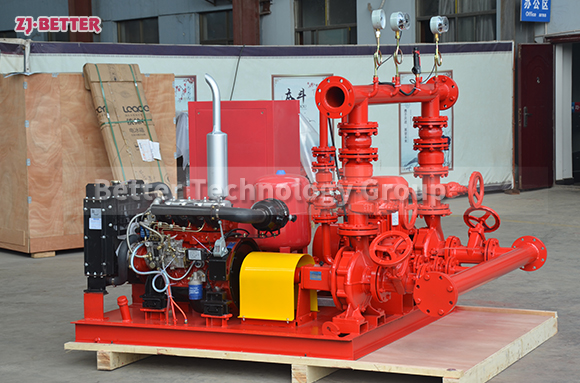

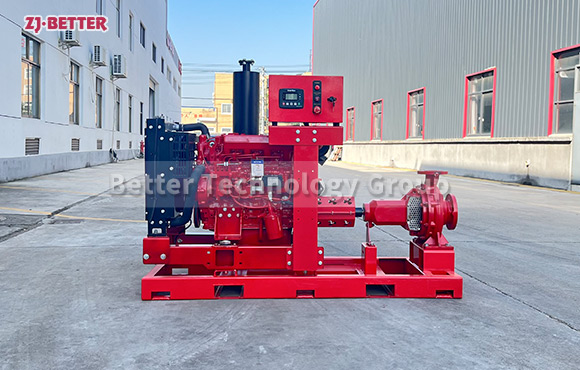

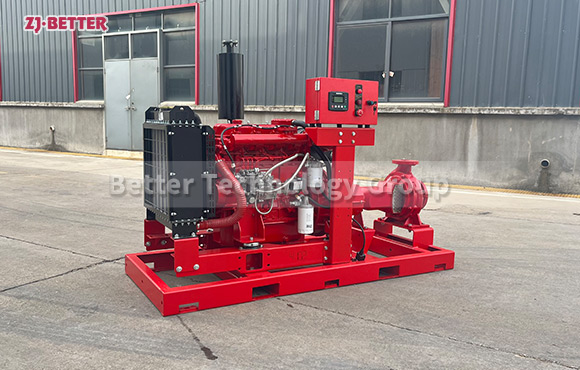

Indeed though all kinds of diesel machine fire pumps on the request feel to be the same in appearance, the accoutrements and quality aren’t the same at different prices. The diesel machine of our company zjbetter adopts high- quality products, has the characteristics of import, has the characteristics of good starting characteristics, strong load capacity, simple use, high degree of robotization, compact structure, and accessible conservation. It’s your secure and dependable fire- fighting outfit.

2. The power force system of the diesel machine fire pump is veritably important

The biggest difference and advantage between the diesel machine fire pump and the general electric water pump is that the diesel machine fire pump set has its own independent power force system, whether it’s stable or not, and whether the power force system is dependable will seriously affect the stability of the diesel machine fire pump.