How to Ensure Proper Ventilation for a Diesel Fire Pump Room?

Why It’s Important:

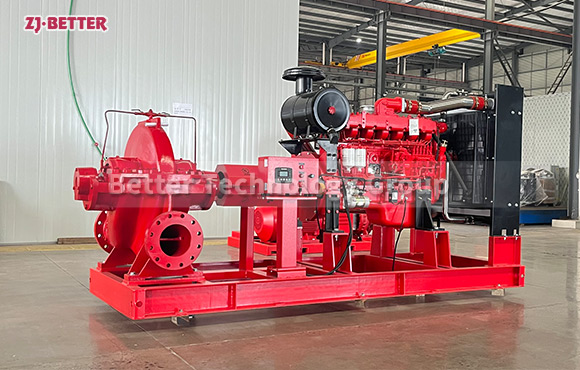

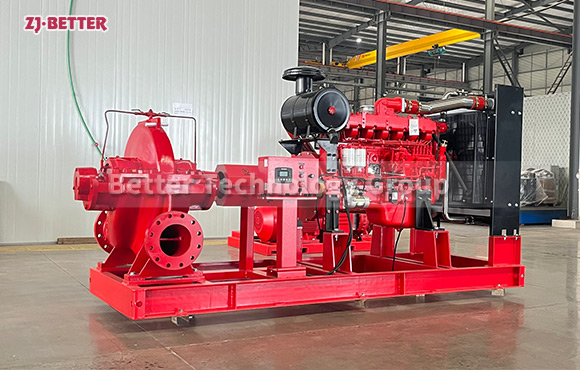

Diesel fire pumps generate heat and exhaust gases that must be properly managed to prevent overheating, maintain engine efficiency, and ensure compliance with NFPA 20 standards.

Best Practices:

Calculate Airflow Needs: Ensure the pump room has adequate airflow to dissipate engine heat and remove exhaust fumes. The required ventilation is based on engine size and heat generation.

Install Proper Louvers & Exhaust Fans: Position intake and exhaust louvers correctly to maintain a steady flow of fresh air. Exhaust fans help remove hot air efficiently.

Direct Radiator Exhaust Properly: If the diesel engine is radiator-cooled, make sure the exhaust is directed out of the building to prevent heat buildup.

Monitor Temperature Levels: Use temperature sensors and alarms to detect overheating risks.

Why It’s Important:

Diesel fire pumps generate heat and exhaust gases that must be properly managed to prevent overheating, maintain engine efficiency, and ensure compliance with NFPA 20 standards.

Best Practices:

- Calculate Airflow Needs: Ensure the pump room has adequate airflow to dissipate engine heat and remove exhaust fumes. The required ventilation is based on engine size and heat generation.

- Install Proper Louvers & Exhaust Fans: Position intake and exhaust louvers correctly to maintain a steady flow of fresh air. Exhaust fans help remove hot air efficiently.

- Direct Radiator Exhaust Properly: If the diesel engine is radiator-cooled, make sure the exhaust is directed out of the building to prevent heat buildup.

- Monitor Temperature Levels: Use temperature sensors and alarms to detect overheating risks.