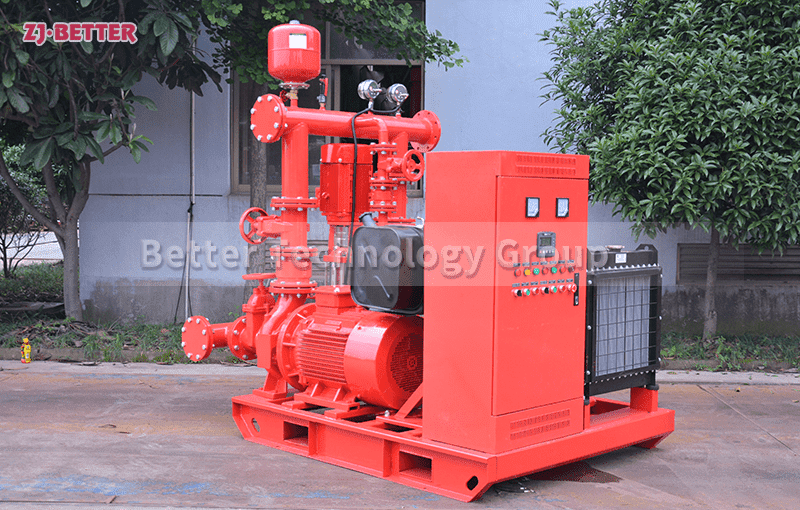

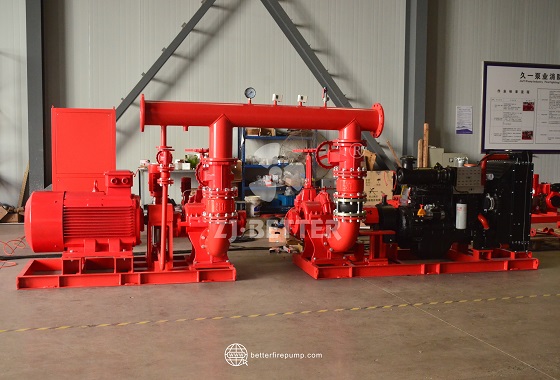

Introduction to the scope of application and structural characteristics of the electric jockey fire pump set

The fire pump can be installed in multiple ways according to the on-site use conditions. And depending on the flow and head requirements, the required flow and head are increased in parallel and series. The bearing adopts low-noise closed bearing, which has been injected with grease before leaving the factory, which can ensure continuous operation for more than two years, and the components have high concentricity. The pump impeller has good performance. Dynamic balance, no vibration in operation, and improved use environment. The pump shaft seal is a mechanical seal, which solves the serious leakage of conventional centrifugal pump packing, increases the service life, and ensures that the operating site is clean and tidy.

The parts that may cause friction when the pump rotates are all made of wear-resistant, corrosion-resistant and high-anti-seize material combinations to ensure reliable operation, reduce noise, and avoid rust water, blocking spray and other fire-fighting devices, extending service life and after shutdown. Rust bite phenomenon.

1. This type of pump is a single-stage multi-stage segmental structure, its suction port is horizontal, and its discharge port is vertically upward. Choose pumps of different sizes and series to be satisfied;

2. This type of pump is mainly composed of water inlet section, middle section, guide vane, impeller, water outlet section, bearing body parts, sealing parts, etc. Its structure design is reasonable;

3. The rotor part of the horizontal fire pump is composed of medium carbon steel shaft, cast iron impeller, balance disc and bushing, etc. Both ends of the rotor are supported on dry oil-lubricated rolling bearings. It can make the pump run very smoothly, with low noise and vibration;