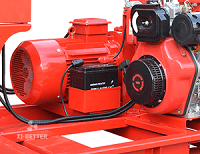

Large Flow EDJ Double Suction Fire Pump

The double-suction fire pump has the characteristics of high lift and large flow, and is widely used in fire fighting. The impeller of this pump type is actually a combination of two back-to-back impellers, and the water flow from the impellers merges into a volute. The double-suction pump has the following characteristics: it is equivalent to two single-suction impellers of the same diameter working at the same time, and the flow rate can be doubled under the same outer diameter of the impeller; the pump casing is horizontally opened, which is convenient for inspection and maintenance. The inlet and outlet of the suction pump are in the same direction and perpendicular to the pump shaft, which is conducive to the arrangement and installation of the pump and the inlet and outlet pipes; the impeller structure of the double suction pump is symmetrical, there is no axial force, and the operation is relatively stable.

Structural features of double suction fire pump:

1. Compact structure: beautiful appearance, good stability and easy installation.

2. Smooth operation: the optimally designed double-suction impeller reduces the axial force to a minimum, and the blade shape with excellent hydraulic performance has been precision cast, and the inner surface of the pump casing and the surface of the impeller are extremely smooth and have significant cavitation resistance. performance and high efficiency.

3. Shaft seal: choose mechanical seal or packing seal. Leak-free operation is guaranteed.

Bearings: NSK high-quality bearings are selected to ensure smooth operation, low noise and long service life.