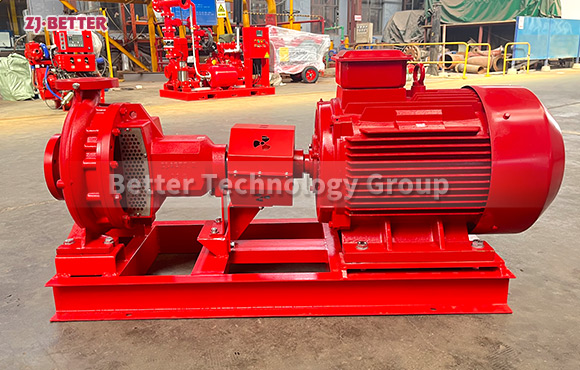

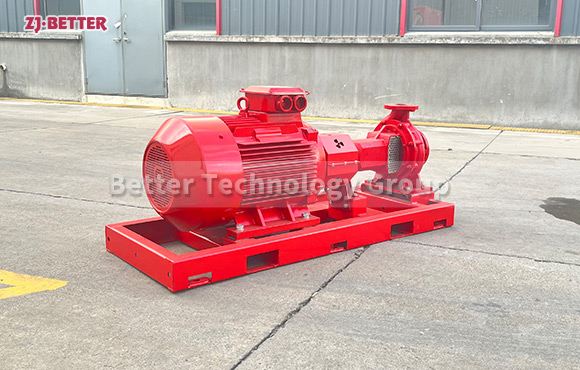

Large Flow Electric Fire Pump

OTS pump is our common name. Its professional name is called single-stage double-suction centrifugal pump. The working principle of OTS pump operation: the impeller is installed in the pump casing and fastened to the pump shaft, which is directly driven by the motor.

The OTS pump body and the pump cover form the working chamber of the impeller. The inlet and outlet flanges are provided with pipe screw holes for installing vacuum gauges and pressure gauges, and the lower part of the inlet and outlet flanges are provided with pipe screw holes for water discharge. The impeller has been checked for static balance and is fixed with the bushing and the bushing nuts on both sides. Its axial position can be adjusted by the bushing nut. The axial force of the impeller is balanced by the symmetrical arrangement of its blades, and there may be some leftovers. The remaining axial force is borne by the bearing at the coaxial end. The pump shaft is supported by two single-row radial ball bearings, which are installed in the bearing bodies at both ends of the pump body and lubricated with butter. The water pump is directly driven by the electric motor through the coupling. The shaft seal is a soft packing seal. In order to cool and lubricate the seal cavity and prevent air from leaking into the pump, there is a water seal ring between the packings. When the pump is working, a small amount of high-pressure water flows into the packing cavity through the water seal pipe to act as a water seal.