Learn where fire pumps can be used

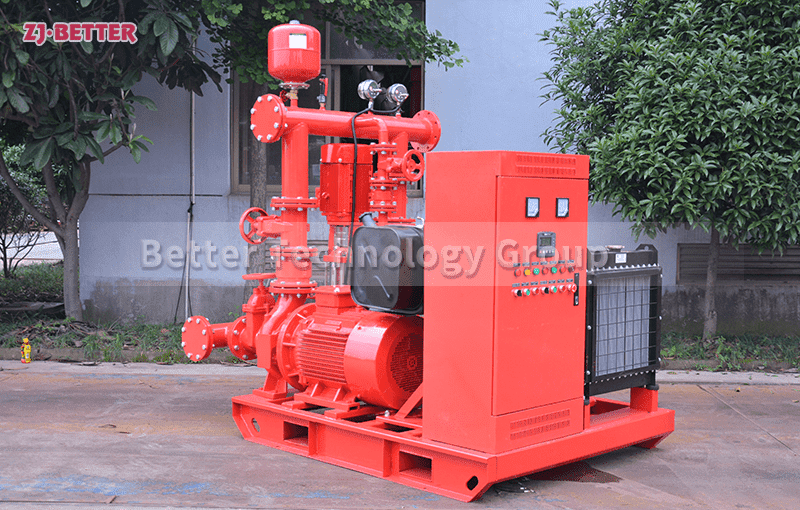

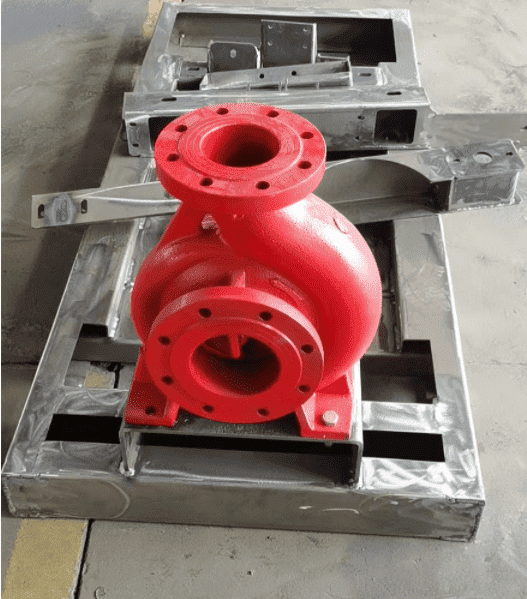

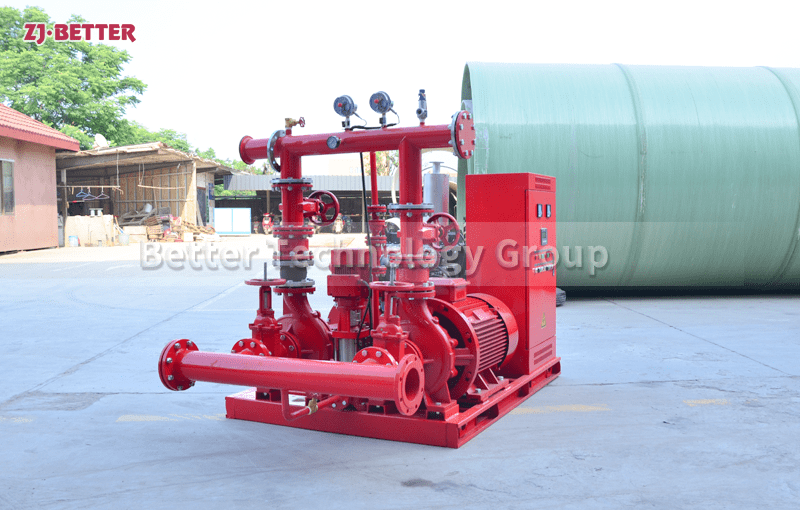

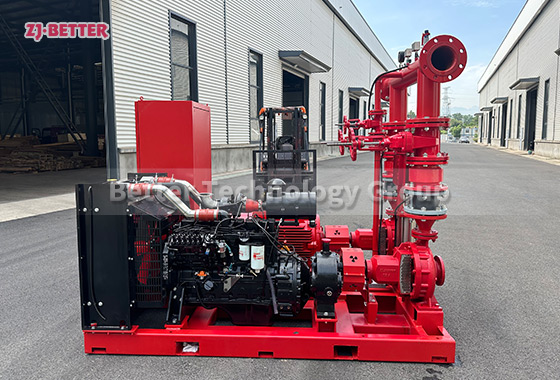

Electric motor fire pumps are used in various water environments, not only for ordinary water supply but also as a good helper for fire water. The electric motor fire pump is manufactured with good structure and technology, with a wide range of performance, simple operation and long-term use. The electric motor fire pump is aimed at various fire water environments, so the selection should also be based on the actual demand environment, performance parameters, etc.

There are different types of fire pumps, which is also to meet the needs of different places. Fire pumps have different structural forms, so that suitable structures can be found in different places, thus meeting the needs of different users. It can be well applied in public places or mobile places.

The fire pump is a device used to supplement water source, foam or pressure products, so as to achieve the purpose of extinguishing fire, so it can ensure the supply of a large amount of fire extinguishing materials when a fire occurs, so as to achieve the purpose of extinguishing fire, so that it can be Help reduce economic losses.